লিফটের ট্রান্সমিশন সিস্টেমে, ট্রাকশন হুইলটি ইস্পাতের তারের রশ্মির মূল লোড-বহনকারী উপাদান হিসাবে কাজ করে, এবং এর গর্তের নির্ভুলতা, সমাক্ষতা এবং পৃষ্ঠের অমসৃণতা সরাসরি লিফট চালানোর মসৃণতা এবং নিরাপদ আয়ু (জাতীয় মান ট্রাকশন হুইলের পরিষেবা আয়ু কমপক্ষে 10 বছর/2 মিলিয়ন স্টার্ট এবং স্টপ হওয়া আবশ্যিক) নির্ধারণ করে। একবার ঘরোয়া শীর্ষস্থানীয় লিফট উৎপাদনকারী প্রতিষ্ঠানটি ট্রাকশন হুইল প্রক্রিয়াকরণে একটি সংকটের মুখোমুখি হয়েছিল: Φ 800-1200mm ডাকটাইল আয়রন (QT600-3) ট্রাকশন হুইলের ক্ষেত্রে, ঐতিহ্যগত প্রক্রিয়াকরণে তিনটি ধাপ প্রয়োজন: "হরাইজন্টাল লেথ রफিং → ভার্টিক্যাল মিলিং মেশিন দিয়ে রশ্মি গর্ত মিলিং → গ্রাইন্ডিং মেশিন দিয়ে প্রিসিশন গ্রাইন্ডিং", যেখানে একক পিসের প্রক্রিয়াকরণ চক্র 45 মিনিট পর্যন্ত হয়; একাধিক ক্ল্যাম্পিং-এর কারণে, অন্তঃছিদ্র এবং রশ্মি গর্তের মধ্যে সমাক্ষতা ত্রুটি প্রায়ই 0.1mm ছাড়িয়ে যায়, যার ফলে 12% হারে তারের রশ্মির অকেন্দ্রিক ক্ষয় হয়; একই সঙ্গে, রশ্মি গর্তের পৃষ্ঠের মেশিনিং নির্ভুলতা অপর্যাপ্ত (0.08mm এর বেশি সহনশীলতা), এবং লিফট চালানোর সময় কম ফ্রিকোয়েন্সির অস্বাভাবিক শব্দ হওয়ার প্রবণতা থাকে। পরবর্তী বিক্রয় অভিযোগের হার যান্ত্রিক বিকলনের 35% গঠন করে।

লিফটের ট্রান্সমিশন সিস্টেমে, ট্রাকশন চাকা ইস্পাতের তারের দড়ির মূল লোড-বহনকারী উপাদান হিসাবে কাজ করে, এবং এর খাঁজের নির্ভুলতা, সমাক্ষতা এবং পৃষ্ঠের অমসৃণতা সরাসরি লিফটের চলাচলের মসৃণতা এবং নিরাপদ আয়ু নির্ধারণ করে (জাতীয় মান অনুযায়ী ট্রাকশন চাকার আয়ু কমপক্ষে 10 বছর/2 মিলিয়ন স্টার্ট ও স্টপ হতে হবে)। একসময় দেশীয় একটি প্রখ্যাত লিফট নির্মাতা প্রতিষ্ঠান ট্রাকশন চাকার প্রক্রিয়াকরণে একটি সমস্যার মুখোমুখি হয়েছিল: Φ 800-1200mm ডাকটাইল আয়রন (QT600-3) ট্রাকশন চাকার ক্ষেত্রে, ঐতিহ্যগত প্রক্রিয়াকরণে তিনটি পদক্ষেপ প্রয়োজন ছিল: "অনুভূমিক লেদ মেশিনে প্রাথমিক কাটিং → উল্লম্ব মিলিং মেশিনে রোপ গ্রুভ মিলিং → গ্রাইন্ডিং মেশিনে নির্ভুল পরিমাপে ঘষা", যেখানে একক পিসের প্রক্রিয়াকরণ চক্র সময় ছিল 45 মিনিট পর্যন্ত; বারবার ক্ল্যাম্পিংয়ের কারণে, অন্তঃছিদ্র এবং রোপ গ্রুভের মধ্যে সমাক্ষতা ত্রুটি প্রায়ই 0.1mm ছাড়িয়ে যেত, যার ফলে তারের দড়ির বিকেন্দ্রীয় ক্ষয়ের হার ছিল 12%; একই সঙ্গে, রোপ গ্রুভ পৃষ্ঠের মেশিনিং নির্ভুলতা যথেষ্ট ছিল না (0.08mm এর বেশি সহনশীলতা), এবং লিফট চালনার সময় কম ফ্রিকোয়েন্সির অস্বাভাবিক শব্দ উৎপন্ন হত। পরবর্তী বিক্রয় অভিযোগের 35% যান্ত্রিক ত্রুটির কারণে হয়েছিল।

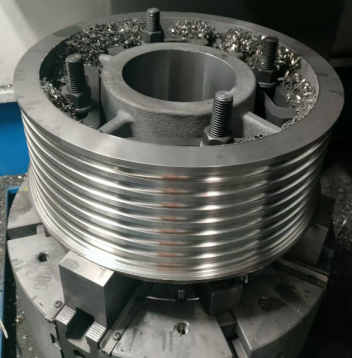

বিশেষ ফিক্সচার

প্রযুক্তিগত উদ্ভাবনের দিক থেকে, ট্র্যাকশন চাকা প্রক্রিয়াকরণের "প্রক্রিয়া একীভূতকরণ"-এ এই সরঞ্জামটি একটি ভাঙন অর্জন করেছে: 21 ইঞ্চি বৃহৎ ব্যাসের চাক (80kN চাপ শক্তি সহ), 8-স্টেশন বৈদ্যুতিক টুল টাওয়ার (1.8 সেকেন্ডে টুল পরিবর্তন সময়), এবং রোপ গ্রুভের জন্য একটি বিশেষ ফর্মড টুল হোল্ডার একীভূত করা। এটি ট্র্যাকশন চাকার অভ্যন্তরীণ ছিদ্র (H7 সহনশীলতা), বাইরের বৃত্ত (IT6 সহনশীলতা), প্রান্ত এবং 6-8 টি রোপ গ্রুভ (গ্রুভ আকৃতি U/V, গ্রুভ গভীরতার সহনশীলতা ± 0.02mm) একবারে প্রক্রিয়া করতে পারে। রোপ গ্রুভের বক্রতল গঠনের কঠিনতা মোকাবেলায় "খণ্ডিত CNC ইন্টারপোলেশন" প্রক্রিয়া গৃহীত হয়। প্রতি বৃত্তে 1000 টি পয়েন্ট থেকে পৃষ্ঠের তথ্য সংগ্রহ করে রোপ গ্রুভের বাসবারের সরলতা 0.015mm/m এ স্থিতিশীলভাবে নিয়ন্ত্রণ করা হয়; বিভিন্ন লোড (1000kg-3000kg) সহ লিফটের জন্য ট্র্যাকশন চাকার স্পেসিফিকেশনের পার্থক্যের প্রতি সাড়া দিতে, সরঞ্জামটিতে 20 সেট প্রক্রিয়া প্যারামিটার টেমপ্লেট রয়েছে, যা ঐতিহ্যগত 2.5 ঘন্টা থেকে পরিবর্তনের সময় 20 মিনিটে কমিয়ে দেয়।

বাস্তবায়নের ফলাফলগুলি লিফট শিল্পের কঠোর মানের সাথে উল্লেখযোগ্যভাবে সঙ্গতিপূর্ণ: একক টুকরো প্রক্রিয়াকরণের চক্র ঘটেছে 45 মিনিট থেকে 28 মিনিটে সংকুচিত, এবং দৈনিক উৎপাদন ক্ষমতা 120 সেট থেকে বেড়ে 210 সেটে পৌঁছেছে; টান চাকার অভ্যন্তরীণ ছিদ্র এবং দড়ির খাঁজের মধ্যে সম-অক্ষতা ≤ 0.05 মিমি তে স্থিতিশীলভাবে নিয়ন্ত্রিত হয়, দড়ির খাঁজের সহনশীলতা ≤ 0.03 মিমি, এবং পৃষ্ঠের অমসৃণতা Ra0.6 μm এ পৌঁছায়, GB/T 13435-2008 "লিফট ট্র্যাকশন মেশিন" মানের প্রয়োজনীয়তা সম্পূর্ণরূপে পূরণ করে; তারের দড়ির কেন্দ্রচ্যুত ক্ষয়ের হার 12% থেকে কমে 1.5% হয়েছে, লিফট চালানোর সময় অস্বাভাবিক শব্দের অভিযোগের হার 90% কমেছে, এবং পরবর্তী বিক্রয় রক্ষণাবেক্ষণ খরচ 40% কমেছে। সরঞ্জামে সজ্জিত বুদ্ধিমান মনিটরিং মডিউল স্পিন্ডেল লোড (নির্ভুলতা ±1%) এবং কাটিং তাপমাত্রা (রেজোলিউশন 0.1 ℃) এর মতো মূল তথ্য বাস্তব সময়ে সংগ্রহ করতে পারে। কাটার ক্ষয় ভবিষ্যদ্বাণী অ্যালগরিদমের সাথে যুক্ত করে, কাটারের আয়ু 35% বাড়ানো হয়েছে, সরঞ্জামের সম্মিলিত ব্যবহারের হার 78% থেকে বেড়ে 92% হয়েছে, এবং বার্ষিক ডাউনটাইম 420 ঘন্টা কমেছে।

VTC60 ট্রাকশন চাকার জন্য 'নির্ভুলতা এবং নিরাপত্তার' দ্বৈত গ্যারান্টি অর্জনের সুযোগ করে দিয়েছে।" কোম্পানির উৎপাদন পরিচালক বলেন, "আমাদের ট্রাকশন চাকা কেবল ইইউ EN 81-1:2020-এর কঠোর সার্টিফিকেশনই পাস করেনি, বরং সুপার হাই-রাইজ লিফট (100 তলার বেশি) এর ট্রান্সমিশন স্থিতিশীলতার চূড়ান্ত প্রয়োজনীয়তা পূরণ করে, যা আমাদের উচ্চপ্রান্তের বৈদেশিক বাজার অন্বেষণের জন্য একটি মূল ভিত্তি তৈরি করেছে।" এই ক্ষেত্রে এটি নিশ্চিত করে যে সিএনসি ভার্টিক্যাল লেথ "কঠোর কাঠামো+নির্ভুল আকৃতি নিয়ন্ত্রণ+প্রক্রিয়া একীভূতকরণ"-এর গভীর সহযোগিতার মাধ্যমে লিফট ট্রাকশন চাকা উৎপাদনের ক্ষেত্রে "নিরাপত্তা ও নির্ভুলতার বোতলের মুখ" অতিক্রম করার জন্য একটি প্রধান সরঞ্জাম হয়ে উঠেছে।