The VMC850 CNC machining center is an advanced equipment specially built for efficient and precision machining. It has excellent rigid structure, adopts high-strength cast iron bed, and has been aged to effectively eliminate internal stress and ensure long-term stability and accuracy retention. The machining center has a long-span X, Y and Z axis stroke, which can easily accommodate large workpiece processing and has a wide range of applications. It is equipped with a high-performance spindle system with large output torque, which can maintain low vibration and high-precision cutting under high-speed operation, and meet the processing needs of milling, boring, drilling and other processing needs of various materials

VMC850 Vertical Machining Center

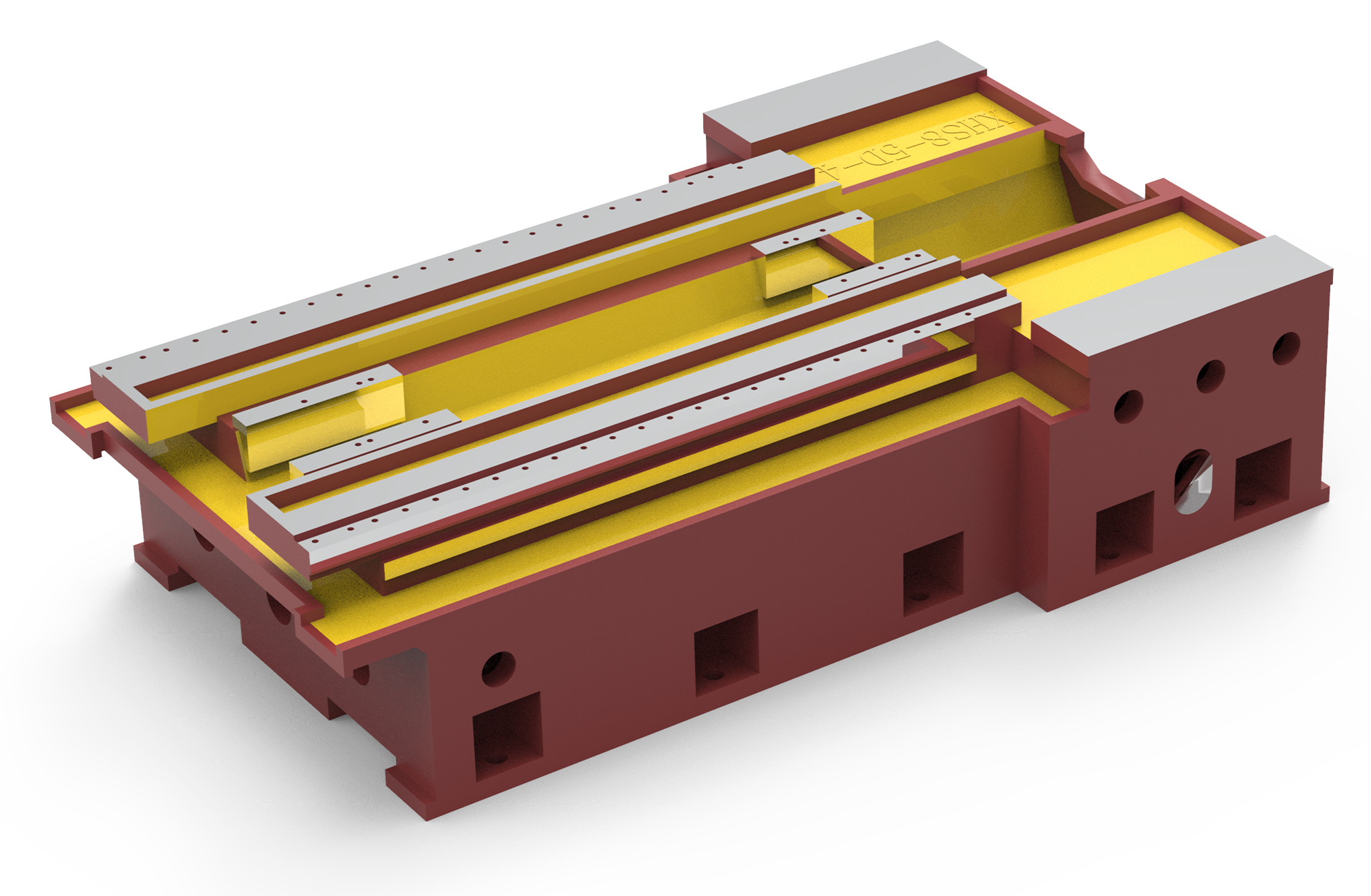

The base of the machine tool is one of the most important parts in the five parts of the whole optical machine, and it is the load-bearing part of the whole machine. The machine tool bed body is made of high-strength cast iron. The casting structure has undergone machine tool dynamics analysis and finite element analysis, and the reinforcing rib structure is reasonably matched to ensure stable organization and permanently ensure quality. The high rigidity of the foundation part is guaranteed. The wide machine tool bed structure and the cross slide table with full load support can ensure the heavy load capacity during processing.

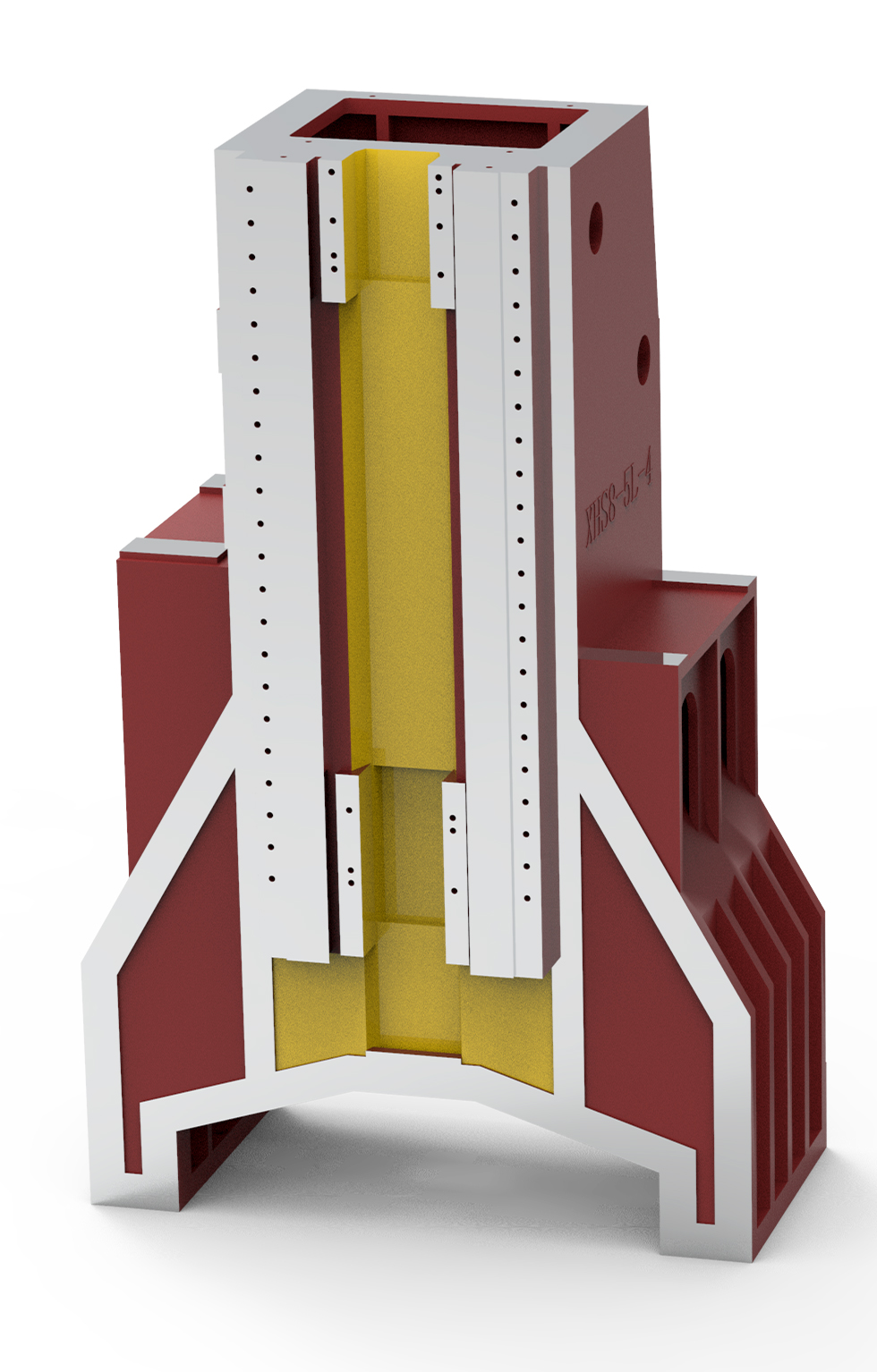

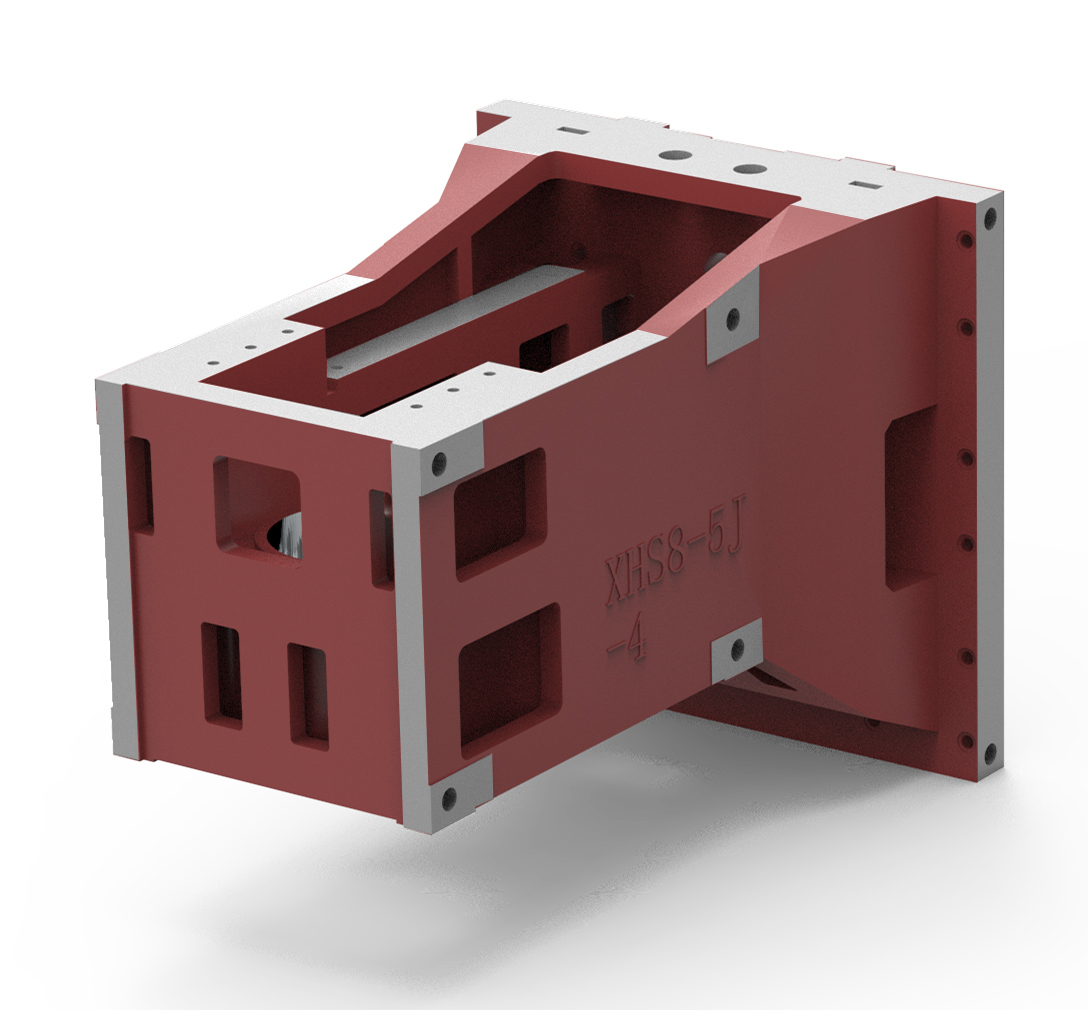

The column adopts a "pagoda-shaped stacking" structure, which conforms to the advanced design concept of material mechanics, and can ensure the heavy load during processing and the vibration generated during high-speed movement, which can not only improve the processing efficiency, but also prolong the service life of the tool.

It ensures the high rigidity of the base part and the heavy load capacity during processing. Fully hardened sliding guide rails, combined with precise grinding processing, combine satisfactory precision quality.

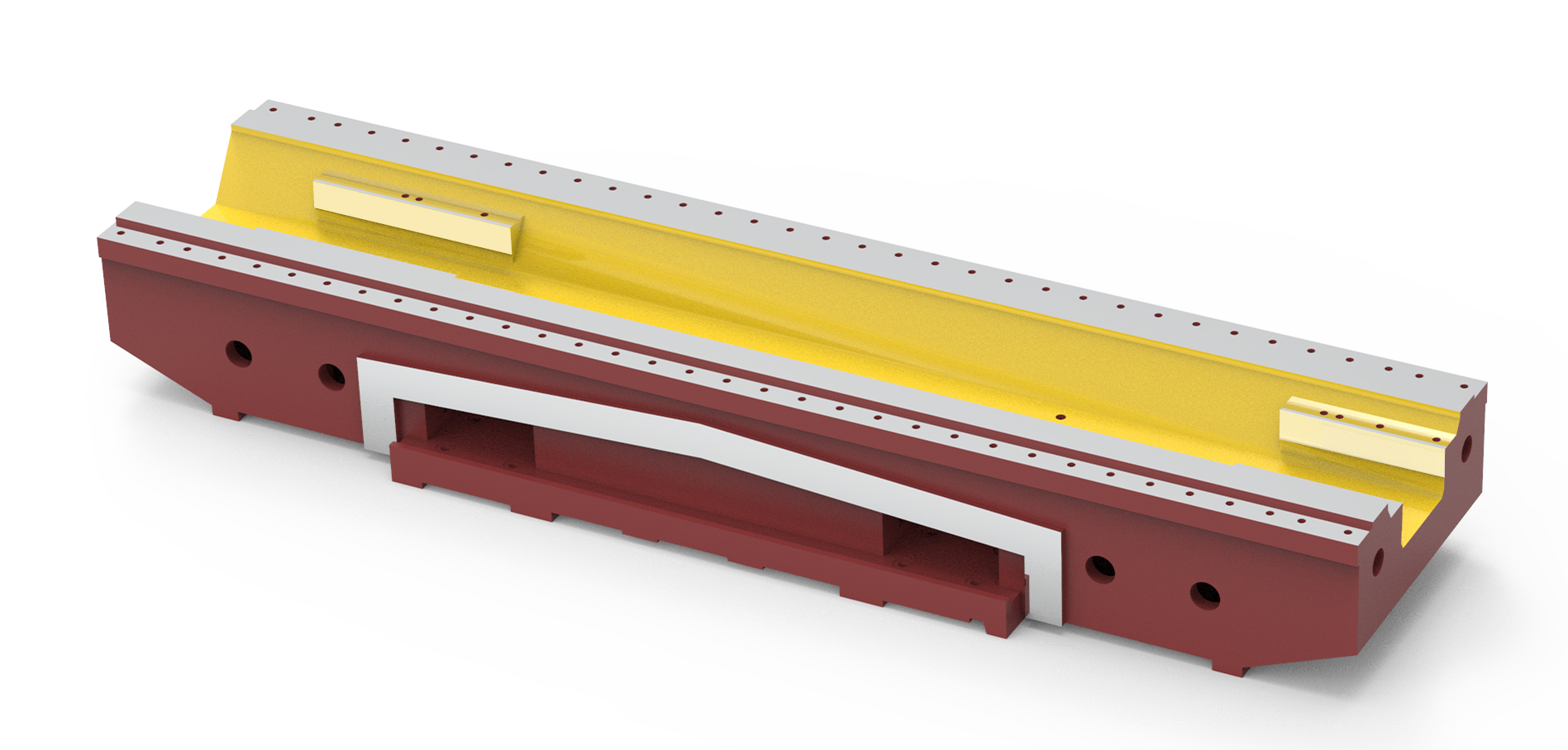

The cross slide table of the machine tool is made of high-strength cast iron. The casting structure has undergone machine tool dynamics analysis and finite element analysis. With reasonable reinforcing ribs and full load support, the cross slide table can ensure the heavy load capacity during processing.

Through finite element analysis of structural statics, dynamics and topological analysis, reasonable structural design and matching of stiffeners, six-slide design structure, and enlarging and widening slide seats make the contact area larger, and improve the overall rigidity of Z axis.

The machine tool worktable is made of high-strength cast iron. The casting structure has undergone machine tool dynamics analysis and finite element analysis, and is matched with reasonable reinforcing ribs to ensure the heavy load capacity during processing under the condition of full load support of the cross slide table. The structure of the machine tool worktable adopts a compound worktable, which can not only increase the strength of the worktable, but also minimize the interference of the fixing bolts of the slide seat on the accuracy of the worktable.

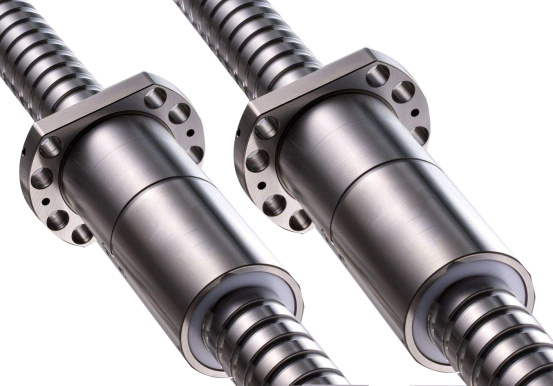

Adopt Taiwan C2/C3 grade high precision, high strength ball screw. The imported high-precision locking nut is adopted, and the ball screw is pre-stretched, which greatly increases the transmission rigidity and eliminates the influence of thermal deformation during movement, thus ensuring the positioning accuracy and repeated positioning accuracy of the machine tool.

The disc (high-speed) servo manipulator tool magazine BT40-24T is adopted, which has fast tool change speed and high efficiency, meets the automation requirements and reduces the failure rate of machine tools.

Maximum tool diameter: Φ100

Maximum tool length: 300mm max

Cutter weight: 7kg

Tool change time (tool-to-tool): 2.2 seconds

The machine tool is equipped with a fully enclosed protective cover, which is beautiful, safe, leakproof and protects the environment. The sealed guide rail protective cover is purchased from the products of Taiwan Province famous brand manufacturers of Sino-US joint venture, which can effectively protect the moving parts of the guide rail and screw and prolong their service life. The spiral automatic chip removal device is simple and environmentally friendly, and is suitable for the transportation of metal and non-metal chips. The machine tool is equipped with a manual air (water) gun (optional), which is easy to remove iron filings.

The machine tool is equipped with a sealed guide rail protective cover, which effectively protects the guide rail and screw and prolongs its service life.

When the machine tool is equipped with three-dimensional full protection, the machine tool is guaranteed not to vibrate during strong chip cutting.

The wiring in the electrical cabinet complies with the national electrical safety specifications to ensure that the control system is free from external interference during operation. Better guarantee production safety.

Equipped with system control oil circuit system: Our original active hydraulic oil supply system is adopted, which is directly controlled by the operating system. The oil supply is automatically distributed according to the movement demand, and the oil supply position and oil quantity are accurately controlled, which greatly reduces the waste of lubricating oil and avoids the contamination of coolant due to lubricating oil, greatly prolongs the use time of coolant and ensures the balance and lubrication of oil supply.

High-precision pitch compensation. Each transmission shaft uses high-precision laser for detection and optimization compensation to make the positioning accuracy of each shaft more accurate and more suitable for processing high-precision parts. At the same time, the advanced ball club instrument is used to optimize the analysis and processing to ensure the accuracy of the machine tool when machining circular and curved surfaces.

A : The conditions and period for the supplier to be responsible for quality: After the machine tool is accepted, it will enter the warranty period, which is twelve months. The equipment implements three guarantees and the warranty period is one year.

B : If the equipment fails during use, the supplier will respond within 2 hours after receiving the notice from the buyer and come up with a solution within 8 hours. If on-site processing is required, personnel will be assigned to the buyer within 48 hours to handle it.

C : If a failure occurs during the warranty period, the supplier will provide free repair services (except for damage to the machine tool caused by human factors by the buyer or the end user); the cost fee will be charged for failures caused by improper use.

D : After the machine tool arrives at the user's factory, if the installation and commissioning work cannot be carried out on time due to the buyer's reasons, the warranty period will expire 12 months after the arrival of the user, and the three guarantees service will no longer be provided.

E : Equipment accuracy standards are provided by the supplier with the contract.

| Main technical parameters table of machine tools | |

|---|---|

| VMC850 | Specifications |

| Machine body material | Secondary tempering (including aging low temperature tempering) Alloy cast iron |

| Airframe structure | Box slider "Pagoda-shaped stacked" column structure |

X.Y.Z axis coordinate travel |

800 * 500 * 500mm |

Workbench specifications (length × width) |

1000 × 500 mm |

Maximum load of worktable |

600 kg |

Spindle centerline to column front rail distance |

625 mm |

| Distance from spindle end face to table plane | 120 ~ 670mm |

| X, Y, Z cutting feed | 1 ~ 10000 mm/min |

| X, Y fast feed rate | 24m/min |

| Z Fast Feed Rate | 20m/min |

| Spindle speed range | 50 ~ 8000 r/min |

| Spindle taper bore | BT40-150mm |

| Spindle motor power | 7.5/11KW |

| Spindle workpiece cooling system | Spindle ring spray function (two water FAW) |

| X-axis servo motor power and connection mode | Direct connection 15nm |

| Y-axis servo motor power and connection mode | Direct connection 18nm |

| Z-axis servo motor power and connection mode | Direct connection 15nm including brake locking |

| X Roller Heavy Duty Line Rail | Four slides for two main load-bearing heavy-load strong line rails Wire rail width 45mm Widening and enlarging of line rail slide |

| Y roller heavy-duty line rail | Four slides for two main load-bearing heavy-load strong line rails Wire rail width 45mm Widening and enlarging of line rail slide |

| Z-axis guide form | Six slides for two main load-bearing heavy-load strong line rails Wire rail width 45mm Widening and enlarging of line rail slide |

| T-shaped groove of worktable (number of grooves × groove width × groove distance) | 5/18/110mm Table Quenching |

| Positioning accuracy | ± 0. 005 mm |

| Repeated positioning accuracy | ± 0. 003 mm |

| Numerical control system | Taiwan New Generation 220MA-5 Including RTCP tip correction Program pre-read function Supports five axis and five linkage functions |

| Lubrication system | Active lubrication system On-demand brake distributed oil filling Real-time monitoring of oil filling status |

| Disc manipulator type tool magazine BT40 | Tool magazine capacity BT40-24 knives Tool Specification BT-40 Maximum tool weight 7Kg Maximum full cutter diameter 75 mm Maximum adjacent cutter diameter 140mm Maximum tool length limit 350mm |

| Airframe cooling tank | Environmentally friendly fully sealed water tank Oil-water separation device Capacity 120L |

| Chip removal device | Automatic chip removal Helical structure Large capacity chip receiving truck |

| External protection | Fully enclosed environmentally friendly protection Waterproof, dustproof, noiseproof and harmful gas proof |

| Internal protection | XY axis stainless steel telescopic protection Large load-bearing type with support pulley Z-axis organ structural protection Fully enclosed protection |

| Source gas pressure used | 0.6-0.8 MPa |

| Machine Contour Dimensions (L × W × H) | 2800 * 2300 * 2650mm |

| Machine tool weight (approx.) | 6500 kg |