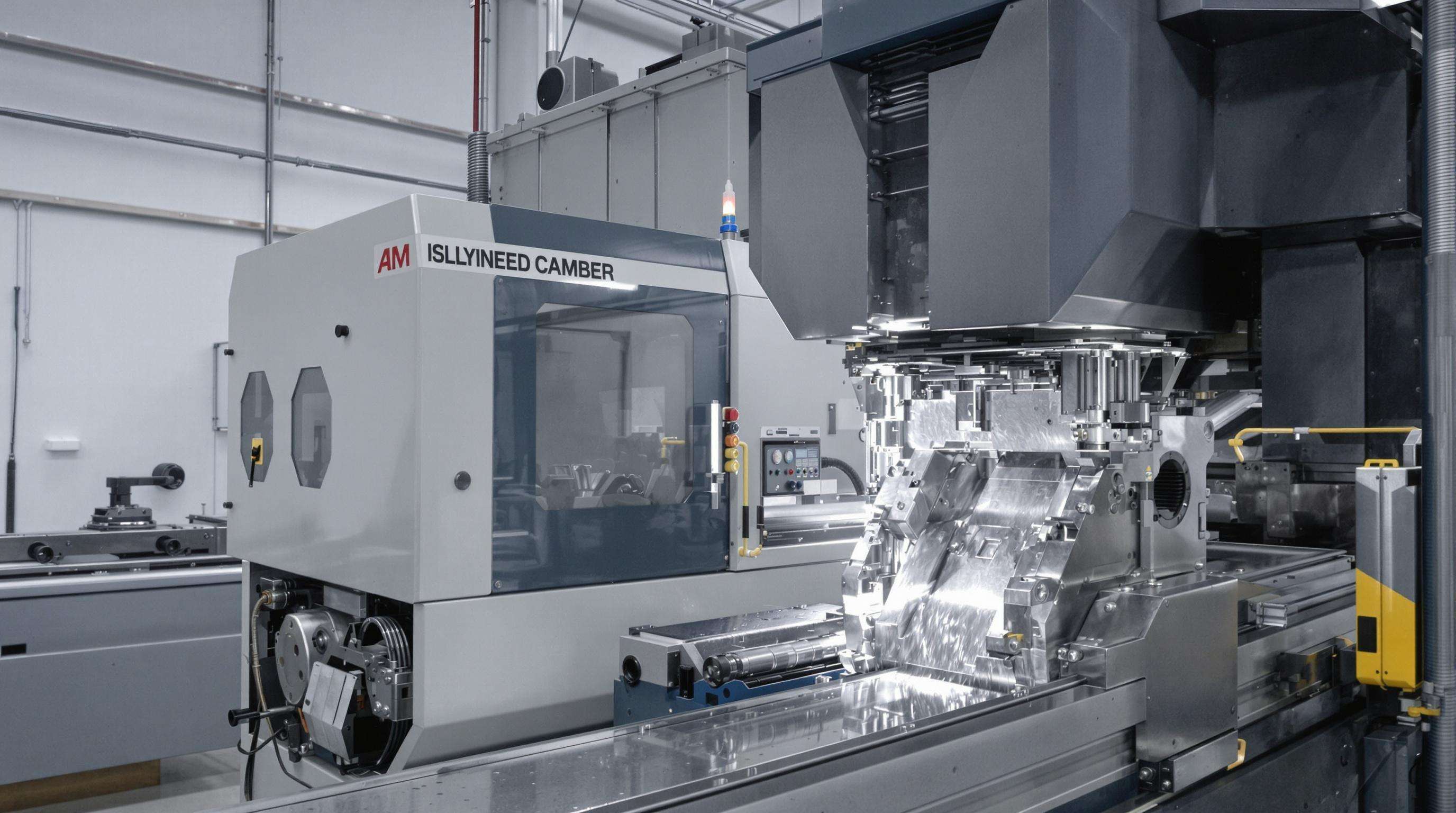

Flat bed machines need extra bolts and parts to get tools at an angle, but inclined bed CNC lathes come with built-in slant angles right from the casting stage, usually around 30 degrees or 45 degrees. The way these machines are made as one solid piece actually gives them about 15 to 20 percent more weight spread out across the machine compared to flat beds. This makes them stay cooler when running hot and less likely to bend under tough cutting conditions. Another big plus is how the slope lets tools reach the workpiece straight on instead of awkward angles, which cuts down on wasted movement especially when doing complicated turning jobs where precision matters most.

This design gives machines a real edge when it comes to running at high speeds too. Spindles can reach up to 6500 RPM while still keeping position accurate down to just 2 microns, which matters a lot when working with tough metals such as titanium or stainless steel. Better yet, top end models come with reinforced box ways that make them even stiffer. These machines handle cutting forces well beyond 1200 Newtons without any annoying chatter issues during operation.

A bed angle between 30 and 45 degrees helps those pesky metal chips drop straight down into the conveyor system instead of building up on the machine's guideways. The whole setup works through simple gravity principles, cutting down on those annoying manual cleaning breaks during busy production runs. According to Machine Tool Insights data from last year, shops report about a 70% reduction in these interruptions when using this design approach. Plus it keeps important parts safe from getting damaged by all that abrasive swarf. Combine this with good quality centralized coolant nozzles and things get even better for maintenance schedules. Shops running inclined bed CNC lathes typically see their ball screws and linear guides needing servicing roughly 92% less often than what happens with older flatbed machines. That kind of difference adds up over time in both downtime and repair costs.

The slanted bed allows cutting tools to approach workpieces at optimal angles, shortening tool paths by 25–40%. This geometric efficiency supports simultaneous multi-axis operations, enabling complex parts to be completed in a single setup while maintaining ±0.001" tolerances.

Standardized turret layouts and quick-clamp tooling systems reduce job changeovers to under 15 minutes—50% faster than conventional lathes. Centralized coolant lines and accessible control panels minimize non-cutting time, increasing daily part output by 35% in automotive component trials.

These machines achieve peak efficiency when paired with automated material handling systems, maintaining 95% uptime during continuous production runs. The inclined design’s natural chip flow complements robotic part removal, enabling fully automated cells that boost annual throughput by 300–400 components per machine.

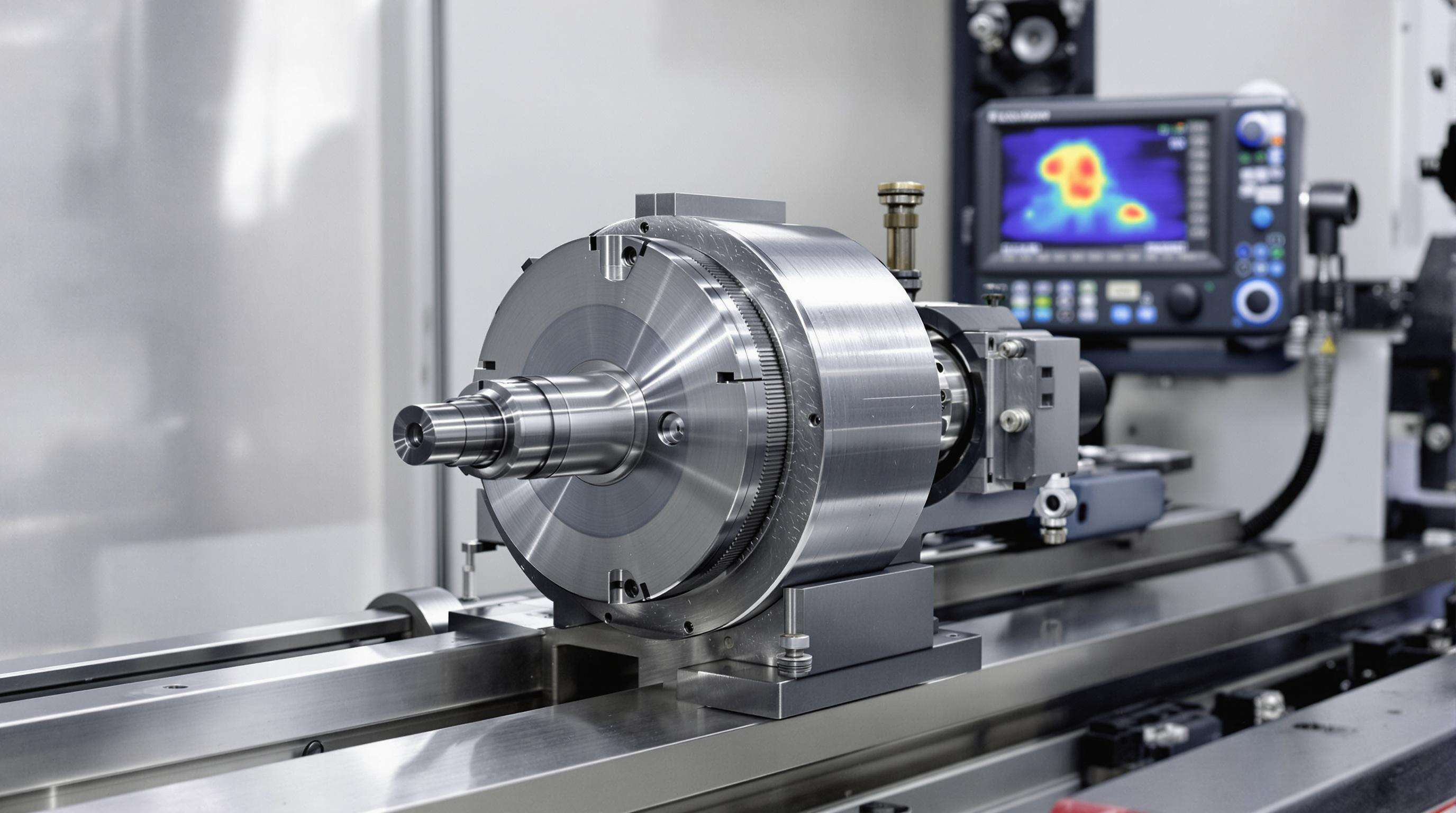

CNC lathes with inclined beds tend to offer better machining accuracy because they handle heat much better than their flat counterparts. When looking at how these machines work, the angled design allows heat to spread out more evenly throughout the machine. This means there's less chance of hot spots forming around critical areas like the spindle and guideways. Some studies suggest this setup can cut down on thermal drift problems by about half when compared to traditional flat bed models according to research published last year. The result? Machines stay aligned properly even after running for long periods, which keeps everything parallel within roughly 2 microns across whatever part is being worked on. For shops dealing with tight tolerances, this makes a real difference in quality control.

Inclined bed lathes have this built-in stiffness that lets them maintain incredible accuracy down to half a micron, which is pretty much required when making parts for airplanes or medical devices. One major company in the aerospace industry actually hit nearly 99.8 percent success rate on those tough titanium turbine pieces because their machines handled vibrations so well. The hardened linear guideways combined with these preloaded ball screws really do the trick against those pesky deflection forces that pop up during fast cutting operations. This setup keeps everything dimensionally consistent even when things get intense on the shop floor.

Servo drives with those fancy 16k pulse per revolution encoders can tweak cutting settings on the fly, which helps compensate when tools start wearing down or materials vary from batch to batch. The closed loop feedback system picks up tiny deviations right around 0.1 microns and gets those axes back on track super fast, usually within just a few milliseconds. Because of this constant error correction, manufacturers achieve surface finishes under Ra 0.2 microns even on really complicated shapes. We've seen this work wonders in actual production environments across different industries.

Inclined bed CNC lathes offer distinct advantages over flat-bed and vertical models in precision and efficiency:

| Feature | Inclined Bed CNC Lathe | Flat Bed CNC Lathe | Vertical CNC Lathe |

|---|---|---|---|

| Best For | High-precision, complex components | Heavy-duty, large-scale parts | Wide-diameter, short workpieces |

| Chip Evacuation | Gravity-assisted, automated | Manual or conveyor-dependent | Gravity-driven but limited by design |

| Space Efficiency | Compact footprint | Larger floor space requirements | Moderate space needs |

| Typical Industries | Aerospace, medical, automotive | Oil/gas, heavy machinery | Energy, general manufacturing |

This comparison underscores why inclined bed CNC lathes dominate precision-driven sectors requiring sub-10µm tolerances.

Inclined bed CNC lathes deliver exceptional performance in mission-critical industries:

Their ability to maintain ±5µm positional accuracy across 10,000+ parts makes them indispensable in high-stakes manufacturing environments.

When looking at machining equipment, the angled design of beds with a 30 to 45 degree slope actually channels those cutting forces into the main frame of the machine instead of putting them on all those parts that move around. What this means is significantly less strain on things like guideways and bearings. Some tests show around an 18 percent drop in stress levels when compared to regular flat beds according to the Precision Machining Technology Report from last year. And because these machines last longer between maintenance checks - about 25% longer in auto manufacturing plants where they run nonstop - it makes sense why shops prefer them. Plus there's something else going on here too. With gravity helping out, chips just naturally slide away from the work area, so we don't get that annoying buildup of tiny metal bits that can really eat away at components over time.

Follow biweekly lubrication cycles using ISO VG 32-grade oil to maintain hydrodynamic film integrity on spindle bearings. Conduct monthly inspections with thermal imaging to detect early signs of misalignment or overheating in servo motors. Key maintenance actions include:

Adhering to manufacturer-recommended preventive maintenance reduces unplanned downtime by 37% and sustains micron-level accuracy over extended runs. Avoid over-lubrication, which attracts chip contamination and is responsible for 22% of avoidable component failures in lathes.