শিল্প উচ্চ-ভোল্টেজ মোটর (10kV এবং তদূর্ধ্ব) উৎপাদন ক্ষেত্রে, মোটরের খোল স্টেটর কোরের জন্য লোড-বহনকারী সাবস্ট্রেট হিসাবে কাজ করে। থামানো ব্যাসের টলারেন্স, অক্ষের সাথে প্রান্ত তলের লম্ব, এবং বিয়ারিং কক্ষের সিলিন্ড্রিসিটি মোটর অপারেশনের স্থিতিশীলতাকে সরাসরি প্রভাবিত করে (জাতীয় মান GB/T 1993-1993 অনুযায়ী থামানো ব্যাসের টলারেন্স IT7 স্তরের হতে হবে, লম্বতা ≤ 0.05mm/m এবং বিয়ারিং কক্ষের সিলিন্ড্রিসিটি ≤ 0.008mm হতে হবে)। Φ 300-600mm ডাক্টাইল আয়রন (QT500-7) এর মোটর হাউজিং প্রক্রিয়াকরণের সময় একটি বড় শিল্প মোটর উৎপাদনকারী একটি ঐতিহ্যবাহী প্রক্রিয়া বাধার মুখোমুখি হচ্ছে: এটি "অনুভূমিক লেথ রफ টার্নিং আউটার সার্কেল → উল্লম্ব বোরিং মেশিন প্রিসিজন বোরিং বিয়ারিং চেম্বার → রকার আর্ম ড্রিলিং মেশিন ইনস্টলেশন হোল প্রসেসিং" এই তিনটি প্রক্রিয়া অতিক্রম করতে হয়। একাধিক ক্ল্যাম্পিং এর ফলে স্টপার এবং বিয়ারিং চেম্বারের মধ্যে কো-অ্যাক্সিয়ালিটি 0.1-0.15mm ছাড়িয়ে যায়, এবং মোটর চালানোর সময় কম্পনের তীব্রতা 1.8mm/s ছাড়িয়ে যায় (যোগ্যতার মান ≤ 1.1mm/s), এবং একক পিসের প্রসেসিং চক্র সময় 75 মিনিট পর্যন্ত হয়; একই সাথে, ডাক্টাইল আয়রন কাটার সময় ঘটিত আন্তঃছর আঘাতের ফলে কঠিন খাদ কাটার সরঞ্জামগুলির আয়ুষ্কাল মাত্র 40-50 পিস/ব্লেড হয়, এবং একক মোটর কেসিংয়ের কাটার সরঞ্জামের খরচ 50 ইউয়ান ছাড়িয়ে যায়।

গ্রাহকের ব্যবহারের পরিস্থিতি

এই সমস্যা কাটিয়ে উঠতে, কোম্পানিটি Kede CNC VTC70 CNC ভার্টিক্যাল লেদ চালু করেছে এবং মোটর হাউজিংয়ের জন্য একটি বিশেষ উৎপাদন ব্যবস্থা গড়ে তুলেছে যা ভারী-দায়িত্বের কঠোর মেশিনিং এবং একক ক্ল্যাম্পিং প্রক্রিয়াকে একত্রিত করে। সরঞ্জামটি একটি অখণ্ড এভিয়েশন গ্রেড কাস্ট আয়রন বেডি (90mm ঢালাই প্রাচীর পুরুত্ব সহ) গ্রহণ করে, যা "12 মাসের প্রাকৃতিক বয়স + 72 ঘন্টার কম্পন বয়স"-এর দ্বৈত চাপ প্রতিরোধ প্রক্রিয়া অতিক্রম করেছে, চার-বিন্দু সমর্থন স্ট্যাটিক প্রেশার গাইড রেল (বহন ক্ষমতা ≥ 50kN)-এর সাথে যুক্ত এবং সীমিত উপাদান বিশ্লেষণের মাধ্যমে কাঠামোগত কঠোরতা অনুকূলিত করা হয়েছে। ব্যাসার্ধীয় কাটিং কঠোরতা 35kN/mm তে পৌঁছায়, যা নমনীয় লৌহ কাটার সময় 22kN ব্যাসার্ধীয় আঘাত লোডকে স্থিতিশীলভাবে সহ্য করতে পারে; FNK CNC সিস্টেম এবং গ্রেটিং রুলার ফুল ক্লোজড-লুপ নিয়ন্ত্রণ (0.05 μm রেজোলিউশন সহ) সহ সজ্জিত, এটি ± 0.007mm পজিশনিং নির্ভুলতা এবং ± 0.01mm পুনরাবৃত্তি পজিশনিং নির্ভুলতা অর্জন করে, যা বিয়ারিং চেম্বারের H6 স্তরের সহনশীলতার প্রয়োজনীয়তার সাথে সঠিকভাবে মিলে যায়। নমনীয় লৌহের বিরতিমূলক কাটিং বৈশিষ্ট্যের প্রতি সাড়া দিতে, সরঞ্জামটি একটি উচ্চ-ক্ষমতার স্পিন্ডেল (45kW) এবং দ্বৈত উচ্চ-চাপ শীতলীকরণ ব্যবস্থা (অভ্যন্তরীণ শীতলীকরণ চাপ 1.2MPa, বাহ্যিক শীতলীকরণ প্রবাহ 40L/min) দিয়ে সজ্জিত, যা অতি-সূক্ষ্ম শস্য WC Co খাদ কাটিং সরঞ্জাম (NbC প্রবলীকরণ পর্যায় যুক্ত, আঘাতের নমনীয়তা ≥ 15MPa · m¹/²) -এর সাথে যুক্ত, যা কার্যকরভাবে সরঞ্জাম চিপিং দমন করে।

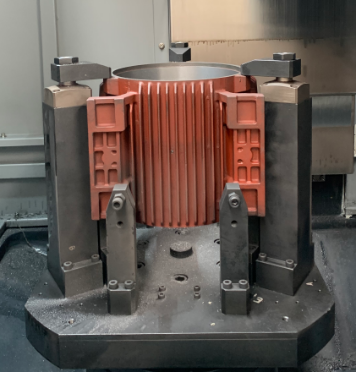

মোটর শেল ক্ল্যাম্পিং

প্রযুক্তিগত উদ্ভাবনের দিক থেকে, মোটর হাউজিং প্রক্রিয়াকরণে "প্রক্রিয়া একীভূতকরণ+ভারী-দায়িত্ব স্থিতিশীল কাটিং"-এ এই সরঞ্জাম দ্বৈত অগ্রগতি অর্জন করেছে: Φ 800mm চার চোয়ালযুক্ত লিঙ্কেজ হাইড্রোলিক চাক (আবদ্ধকরণ বল 150kN পর্যন্ত), 8-স্টেশন সার্ভো টারেট (1.6 সেকেন্ডে টুল পরিবর্তনের সময়) এবং রেডিয়াল পাওয়ার টুল হেড (350N·m আউটপুট টর্ক) একীভূত করে, এটি মোটর হাউজিংয়ের বাইরের বৃত্তের নির্ভুল টার্নিং (IT6 সহনশীলতার স্তর), বিয়ারিং কক্ষের নির্ভুল বোরিং (সিলিন্ড্রিসিটি ≤ 0.006mm), স্টপ ফরমিং (ব্যাসের সহনশীলতা ± 0.015mm), প্রান্তের মিলিং (সমতলতা ≤ 0.03mm), এবং 20-24 টি ইনস্টলেশন ছিদ্র ড্রিলিং ও ট্যাপিং (অবস্থানগত সহনশীলতা ≤ 0.1mm) একসঙ্গে সম্পন্ন করতে পারে। সম-অক্ষতা নিয়ন্ত্রণের কঠিনতা মোকাবেলায়, আমরা উদ্ভাবনমূলকভাবে "বেঞ্চমার্ক একীভূত প্রক্রিয়াকরণ পদ্ধতি" গ্রহণ করেছি: মোটর হাউজিংয়ের উভয় প্রান্তের অভ্যন্তরীণ ছিদ্রগুলিকে অবস্থান নির্ধারণের বেঞ্চমার্ক হিসাবে নিয়ে, মেশিনে মাপার সিস্টেমের মাধ্যমে (± 0.001mm পরিমাপের নির্ভুলতা) বাস্তব সময়ে প্রক্রিয়াকরণ তথ্য সংগ্রহ করা হয়, কাজের টুকরার ওজনের কারণে ঘটা ট্রেস বিকৃতির জন্য গতিশীলভাবে ক্ষতিপূরণ করা হয়, যাতে স্টপার এবং বিয়ারিং কক্ষের মধ্যে সম-অক্ষতা স্থিতিশীলভাবে ≤ 0.04mm এ নিয়ন্ত্রণ করা যায়। তাপ বিকিরণ প্রাচীরের মতো জটিল কাঠামোর ক্ষেত্রে, সরঞ্জাম Y-অক্ষ এবং C-অক্ষ লিঙ্কেজ ইন্টারপোলেশন ব্যবহার করে ত্রিমাত্রিক তলের এককালীন ফরমিং সম্পন্ন করে, যা ঐতিহ্যবাহী প্রক্রিয়া স্থানান্তরের কারণে হওয়া টুল দাগ এড়ায়।

বাস্তবায়নের ফলাফলগুলি শিল্প উচ্চ-ভোল্টেজ মোটরের মানগুলির সাথে সম্পূর্ণরূপে খাপ খায়: একক পিসের প্রক্রিয়াকরণ চক্র 75 মিনিট থেকে কমিয়ে 42 মিনিটে নামানো হয়েছে, এবং দৈনিক উৎপাদন ক্ষমতা 120 সেট থেকে বৃদ্ধি করে 220 সেটে উন্নীত করা হয়েছে; মোটর হাউজিংয়ের বিয়ারিং চেম্বারের বেলনাকারতা ≤ 0.006 মিমি, স্টপার এবং বিয়ারিং চেম্বারের মধ্যে সমঅক্ষতা ≤ 0.04 মিমি, এবং প্রান্ত তল থেকে অক্ষের লম্বভাব ≤ 0.03 মিমি/মি, যা GB/T 1993-1993 "ঘূর্ণায়মান বৈদ্যুতিক মেশিনের জন্য শীতলকরণ পদ্ধতি" এবং IEC 60034-1 মানদণ্ডের প্রয়োজনীয়তা পুরোপুরি পূরণ করে; মোটর চলাকালীন কম্পনের তীব্রতা 1.8 মিমি/সেকেন্ড থেকে কমে 0.8 মিমি/সেকেন্ড হয়েছে, এবং কম্পন অতিরিক্ত হার 22% থেকে কমে 1.5%-এ নেমে এসেছে; আঘাত প্রতিরোধী ডিজাইনের কারণে টুলের আয়ু 60% বৃদ্ধি পেয়েছে (প্রতি ব্লেডে 65-80 পিস পর্যন্ত), এবং একক মোটর কাঠামোর টুলের খরচ 32 ইউয়ানে কমে গেছে; সরঞ্জামে স্থাপিত বুদ্ধিমান ডায়াগনস্টিক সিস্টেম স্পাইন্ডেল কম্পন ত্বরণ (নমুনা ফ্রিকোয়েন্সি 1 কিলোহার্টজ) এবং কাটিং বলের ওঠানামা বাস্তব সময়ে নজরদারি করতে পারে। একটি টুল ক্ষয় ভবিষ্যদ্বাণী মডেলের সাথে একত্রিত হয়ে, সরঞ্জামের সম্মিলিত ব্যবহারের হার 76% থেকে বৃদ্ধি করে 93%-এ পৌঁছেছে, এবং বার্ষিক ডাউনটাইম 480 ঘন্টা কমেছে।

VTC70 আমাদের উচ্চ-ভোল্টেজ বৈদ্যুতিক ক্যাসিংয়ের 'ভারী ধরনের মেশিনিং এবং নির্ভুল নিয়ন্ত্রণ'-এর মধ্যকার দ্বন্দ্ব সমাধান করে। কোম্পানির প্রধান ইঞ্জিনিয়ার বলেছেন, 'আমাদের 20MW উচ্চ-ভোল্টেজ মোটর শুধুমাত্র CE সার্টিফিকেশন পাস করেই নয়, পারমাণবিক বিদ্যুৎকেন্দ্র এবং বৃহৎ পরিসরের রাসায়নিক শিল্পের মতো গুরুত্বপূর্ণ ক্ষেত্রগুলিতে সরঞ্জামের 100000 ঘন্টার ত্রুটিহীন কার্যকারিতা চাহিদা পূরণ করে। এটি আমাদের উচ্চ-প্রান্তের বাজার অন্বেষণের জন্য কার্যকর প্রতিযোগিতামূলক সুবিধা প্রদান করে।' এই ক্ষেত্রে নিশ্চিত হয় যে, "ভারী ধরনের কাঠামোগত ডিজাইন + প্রক্রিয়া একীভূতকরণ উদ্ভাবন + বুদ্ধিমান নির্ভুল নিয়ন্ত্রণ"-এর গভীর সহযোগিতার মাধ্যমে শিল্প উচ্চ-ভোল্টেজ বৈদ্যুতিক ক্যাসিং উৎপাদন ক্ষেত্রে গুণমান এবং দক্ষতা বাধা অতিক্রম করার জন্য সিএনসি উল্লম্ব লেথ এখন একটি প্রধান সরঞ্জাম হয়ে উঠেছে।