In the fields of petrochemicals and oil and gas transportation, flanges are the core connecting components of pipeline systems. The flatness of the sealing surface, the position of bolt holes, and the stability of material processing directly determine the safety of pipeline operation (for major events such as explosions and environmental pollution caused by flange leaks in oil and gas pipelines, the national standard requires flange sealing surface flatness to be ≤ 0.03mm/100mm, and bolt hole indexing error to be ≤ ± 5 ′). A leading domestic petrochemical equipment manufacturer once faced a bottleneck in flange processing: for DN400-DN1200mm flanges (materials include Q345R carbon steel, 316L stainless steel, 12Cr1MoVG alloy), traditional processing requires three processes: "horizontal lathe rough turning → vertical lathe precision turning sealing surface → rocker arm drilling machine drilling bolt holes", with a single processing cycle of up to 45 minutes; Due to multiple clamping, the coaxiality between the flange inner hole and the sealing surface often exceeds 0.08mm, and the flatness error of the sealing surface reaches 0.06-0.09mm, resulting in a pipeline pressure test leakage rate of 8%; At the same time, stainless steel flanges are prone to work hardening during high-speed cutting, with surface roughness exceeding Ra1.6 μ m, requiring additional polishing processes, and increasing the labor cost of a single flange by 18 yuan.

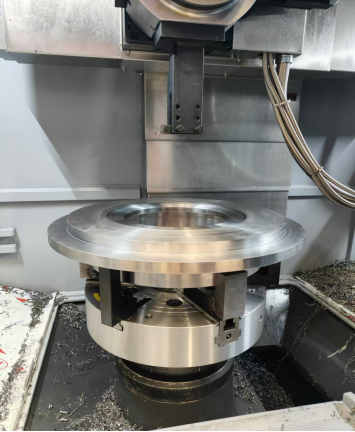

Processing site

To overcome this dilemma, the company introduced the Zhongjie Friendship Machine Tool VTC100A CNC vertical lathe and built a flange exclusive processing system with "one-time clamping and full process completion". The equipment adopts an integral thick walled cast iron bed body (with a wall thickness of up to 80mm), which has undergone dual stress relief treatment of vibration aging and natural aging. Combined with the cross slide table heavy-duty design, the rigidity distribution is optimized through finite element analysis. The radial cutting stiffness reaches 32kN/mm, which can stably withstand the 22kN radial cutting force during alloy flange cutting; Equipped with Siemens 828D Advanced CNC system and fully closed-loop control of grating ruler (resolution 0.1 μ m), it achieves ± 0.002mm positioning accuracy and ± 0.001mm repeated positioning accuracy, accurately matching the flatness requirement of flange sealing surface of ± 0.02mm. For different material characteristics, the equipment is equipped with a dual channel spindle cooling system: emulsion cooling is used for processing carbon steel (cooling efficiency ≥ 95%), and oil mist cooling is switched for processing stainless steel (droplet diameter 5-10 μ m), combined with ultra-fine grain hard alloy cutting tools (TiAlN coated cutting tools with WC Co content of 92% are used for processing stainless steel), effectively suppressing work hardening and chip deposits, ensuring stable surface roughness.

In terms of technological innovation, the equipment has achieved a dual breakthrough of "process integration+material adaptation" in flange processing: integrating a Φ 32mm three jaw power chuck (with a clamping force of 120kN, suitable for DN750-DN1000mm flange clamping requirements), a 24 station servo turret (tool change time of 1.5 seconds), and a CNC indexing disc (indexing accuracy ± 3 ′), which can complete the processing of flange inner holes (tolerance H8), outer circles (tolerance IT7), sealing surfaces (tenon groove surface/concave convex surface, flatness ≤ 0.03mm), and 8-24 bolt holes (aperture tolerance H9, indexing error ≤± 4 ′) in one go. For precision machining of sealing surfaces, we innovatively adopt the "spiral interpolation precision machining process". Through surface data acquisition and compensation at 500 points per circle, the flatness of the sealing surface is stably controlled at 0.02mm/100mm; In response to the high temperature strength characteristics of alloy flanges (12Cr1MoVG), the equipment is equipped with a built-in material and process database, which automatically matches cutting parameters (spindle speed 800-1200r/min, feed rate 60-100mm/min) to avoid tool breakage; For multi specification flange replacement, the equipment supports one click adjustment of process parameters (with 30 sets of flange processing templates built-in), reducing the replacement time from traditional 2 hours to 18 minutes.

Flange clamping

The implementation results fully comply with the strict standards of the petrochemical industry: the single processing cycle has been compressed from 45 minutes to 32 minutes, and the daily production capacity has been increased from 150 sets to 260 sets; The coaxiality between the flange inner hole and the sealing surface is stably controlled at ≤ 0.04mm, the flatness of the sealing surface is ≤ 0.03mm, the surface roughness reaches Ra0.8 μ m, and the bolt hole indexing error is ≤± 3.5 ′, fully meeting the requirements of GB/T 9113.1-2022 "Integral Steel Pipe Flanges" and ASME B16.5 "Pipe Flanges and Flange Fittings" standards; The leakage rate of pipeline pressure testing has been reduced from 8% to 0.5%, and the manufacturing cost of single flanges has been reduced by 15 yuan after the polishing process is cancelled; For 316L stainless steel flanges, the tool life is extended by 40% due to oil mist cooling and parameter optimization. The intelligent diagnostic module equipped on the equipment can monitor the spindle load (accuracy ± 0.5%) and cutting temperature (resolution 0.1 ℃) in real time. Combined with the tool wear prediction algorithm, the comprehensive utilization rate of the equipment has been increased from 80% to 94%, and the annual downtime has been reduced by 380 hours.

CK5263 has completely solved the dual problem of 'sealing safety and processing efficiency' for flanges. ”The manufacturing director of the company stated, 'Now our flanges have not only passed the rigorous testing of the National Petroleum Pipe Quality Supervision and Inspection Center, but also meet the ultimate requirements for high-pressure flanges (PN40) in major projects such as the West East Gas Pipeline 3, which has built a technical barrier for our competition in the petrochemical equipment field.'. ”This case confirms that CNC vertical lathes have become the core equipment in the field of petrochemical equipment flange manufacturing to break through the bottleneck of "safety accuracy and efficiency" through the deep integration of "rigid structure adaptation+material and process customization+precision closed-loop control".