In the world of manufacturing, every second is important. CNC machining center is usually the start of a production line when working with auto parts, new energy motor shells, or even aerospace precision components. Having one isn't the only important thing. You need to figure out how to best utilize one to save money, improve speed, and maintain quality. Lets explore some valuable insights drawn from seasoned professionals in the field to maximize CNC machining efficiency.

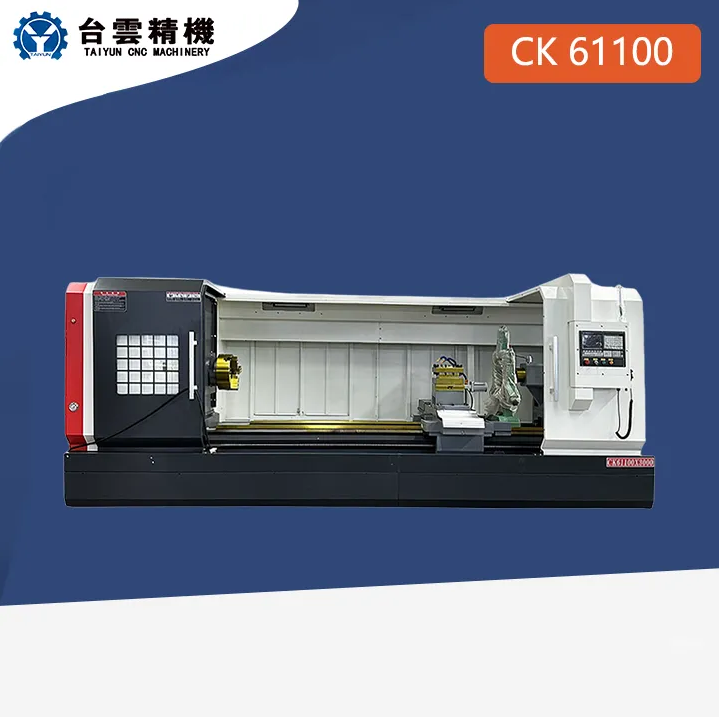

You cannot maximize efficiency without first understanding all that your CNC machining center has to offer. Understanding your CNC machining capabilities will improve CNC machining efficiency and put the CNC machining center to good use. Different machines perform different tasks. CNC machines can be divided into categories like vertical CNC lathes, horizontal CNC lathes, and slant bed CNC turning and milling combinations. For instance, vertical CNC lathes can handle large components like elevator traction wheels, while slant bed CNC lathes are more suited for small, intricate components like auto parts.

Some manufacturers design custom solutions for CNC machining centers. Rather than trying to adapt an unsuitable machine to a job, you can collaborate with providers to receive a setup that is designed for your specifications. This greatly reduces the number of mid-production adjustments that need to be made. Consider a custom CNC machining center designed for your new energy motor shell or photovoltaic graphite guide tube. You are likely to spend less time correcting mistakes and more time producing quality parts. Understanding these fundamental capabilities allows you to accurately allocate tasks to the appropriate machine, eliminating time lost due to mismatches.

A poorly organized production process will result in even the best CNC machining centers underperforming. The ultimate goal of production process organization is to minimize wasted time for each step of the process, including material prep and part finishing. The pre-production phase directly affects processes, so consider your options to improve overall efficiency. Undimensioned drawings or drawings with conflicting specifications will result in rework and time waste. Many seasoned teams concentrate on this step, which is ultimately why they always meet deadlines.

Another approach to process optimization is effective supply chain management. Your CNC machining center's value is less than the production parts it processes as well as the machine itself. Reliable supply chain partners will provide the appropriate machine components and lower the likelihood of machine breakdowns. This approach also improves overall equipment efficiency as it eliminates downtime due to external supply chain breakdowns or defective parts. Supply chain breakdowns due to defective parts will improve the overall efficiency of your CNC machining center as it eliminates downtime due to external supply chain breakdowns or defective parts.

Lastly, don't forget about how you manage production scheduling. You have to remember that jumping from big simple jobs to small detailed jobs without properly accounting for setup times results in a loss of efficiency. Whenever possible try to cluster similar jobs, this way you won’t have to adjust the CNC machining center as often. This kind of scheduling is how teams optimize machine use while minimizing downtime.

Don’t forget about the maintenance of the CNC machining center as well. You don’t want to be left behind as technology and software become more advanced. This is especially true for brands that have significant R&D expenditures. Having access to the latest software that automatically optimizes cutting paths gives you a huge advantage. For example, the machining cycle time is drastically reduced for parts like commercial vehicle brake drums while also ensuring safety standards for double-sided parallelism and end face runout.

Owning the latest technology does not excuse you from regular maintenance. Long-term care on a CNC machining center improves reliability. Small issues, like a bearing starting to wear out or a sensor becoming dirty, can result in big issues that halt production. Look for service providers with reliable after-sales service to help you keep your machine in tip-top shape. Whether you need a routine check or a machine repair, serviceability allows you to address problems quickly so you can return to production.

Maintenance informs innovation. If your CNC machining center received a recent upgrade that includes new sensors for the R&D team, regular maintenance will ensure that the sensors function accurately so that you can depend on the machine's reading and avoid expensive errors. The combination of new technology and maintenance will assure that your efficiency is sustained.

Looking at real-world examples can be best for learning how to maximize your CNC machining center’s efficiency. Consider new energy vehicle wheels. These parts must be lightweight to improve the car’s range and super precise for safety. One CNC machining center approach that works is high-speed, high-precision cutting. As the machine's spindle speed and tool selection are adjusted for the wheel’s material (aluminum alloy), manufacturers can reduce machining time while keeping the wheel strong and balanced. This isn’t just theory, it’s a solution that’s been successfully applied to mass-produced new energy vehicle parts.

Another example is the photovoltaic grade isostatic graphite guide tubes. These tubes (usually 300-500mm in diameter and 400-600mm long) must have smooth inner walls to guide the silicon melt and insulate the thermal field. A CNC machining center can accomplish this by advanced cooling systems and steady feed rates, thus mitigating the risk of graphite cracking and ensuring the tube meets insulation standards. The key is the machine’s features are matched to the part’s unique needs. Again, the CNC machining center isn’t just “running a job” — it’s tailored to the task. This cuts down on waste and speeds up production.

These scenarios illustrate that efficiency isn't simply cranking up the speed on the CNC machining center to make it work quicker. It consists of knowing the part's specifications well, taking the proper time to setup the machine, and implementing tried-and-true methods to mitigate the risk of errors. You can use the same principles showcased in the case studies in your own operation.

Maximizing efficiency on a CNC machining center can seem difficult. However, it simply comes down to the basics. Understand the machine’s capabilities, optimize your workflow, manage your technology and maintenance, and use your industry benchmarks to guide you. It doesn't matter if you are producing automotive components, new energy parts, or parts for the aerospace industry, applying these recommendations will optimize your CNC machining center, improve machining time, reduce cost, and maintain quality. In case you require additional support, skilled CNC solution providers can be contacted. They will assist you in adjusting your configuration.