Parameters for Efficient Metal Cutting

Master the 3 core metal cutting parameters—speed, feed, depth of cut—and how they interact. Optimize for tool life, surface quality & cost. Download expert guide.

2026-01-13

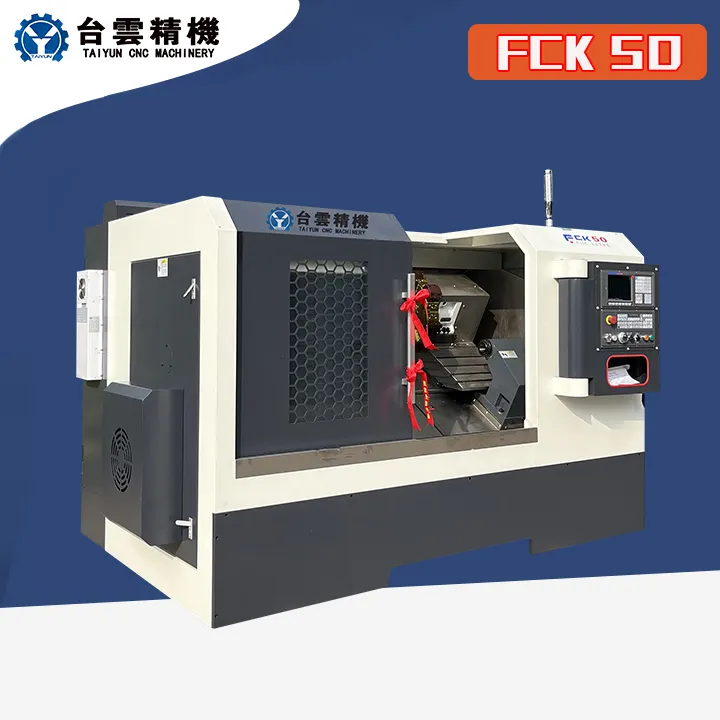

Discover how inclined bed CNC lathes reduce vibration, improve chip evacuation, and enhance machining accuracy for automotive and new energy parts. Learn the real-world impact on performance and uptime. Explore the advantages today.

Struggling with complex part production? 5-axis CNC machining delivers unmatched precision, 40% faster turnaround, and superior surface finishes. Discover how it reduces costs and simplifies manufacturing. Learn more now.

Discover what materials a CNC lathe can machine—from steel and aluminum to plastics and titanium. Optimize your manufacturing with expert tips on tooling and settings. Learn more.

Struggling with CNC downtime or inefficiency? Discover how to boost productivity, reduce costs, and maintain precision with expert-backed strategies. Learn more now.

Discover how CNC lathes like the Taiyun KD800 achieve ±0.0012mm precision, boost efficiency, and ensure safety in manufacturing. Learn why they outperform manual machines. Explore now.

Discover how smart factories, AI-driven digital twins, and advanced materials are reshaping precision manufacturing. See how additive and CNC hybrid methods boost efficiency. Explore the future of production.

In mechanical transmission systems, the radial runout (requirement ≤0.05mm) and face runout (≤0.04mm) of gears with a pitch circle diameter of Φ300-500mm directly determine the transmission efficiency and equipment lifespan. A heavy-duty ge...

Discover how CNC machining enables high-precision engine, drivetrain, and safety components in the automotive industry. Learn about lightweight materials, tight tolerances, and production efficiency gains driving innovation. Explore real-world applications and future trends.

In the manufacturing field of industrial high-voltage motors (10kV and above), the motor housing serves as the load-bearing substrate for the stator core. The tolerance of the stop diameter, the perpendicularity of the end face to the axis, and the c...

Discover the key factors affecting CNC machining lead time, from cutting parameters to material selection and setup optimization. Reduce cycle times and boost productivity—learn how.

Achieve ±0.005mm accuracy in metal fabrication with advanced CNC, robotic welding, and real-time QC. Discover how to reduce errors by 40% and ensure compliance. Partner with certified experts today.

In the elevator transmission system, the traction wheel serves as the core load-bearing component of the steel wire rope, and its groove accuracy, coaxiality, and surface roughness directly determine the smoothness and safety life of the elevator ope...