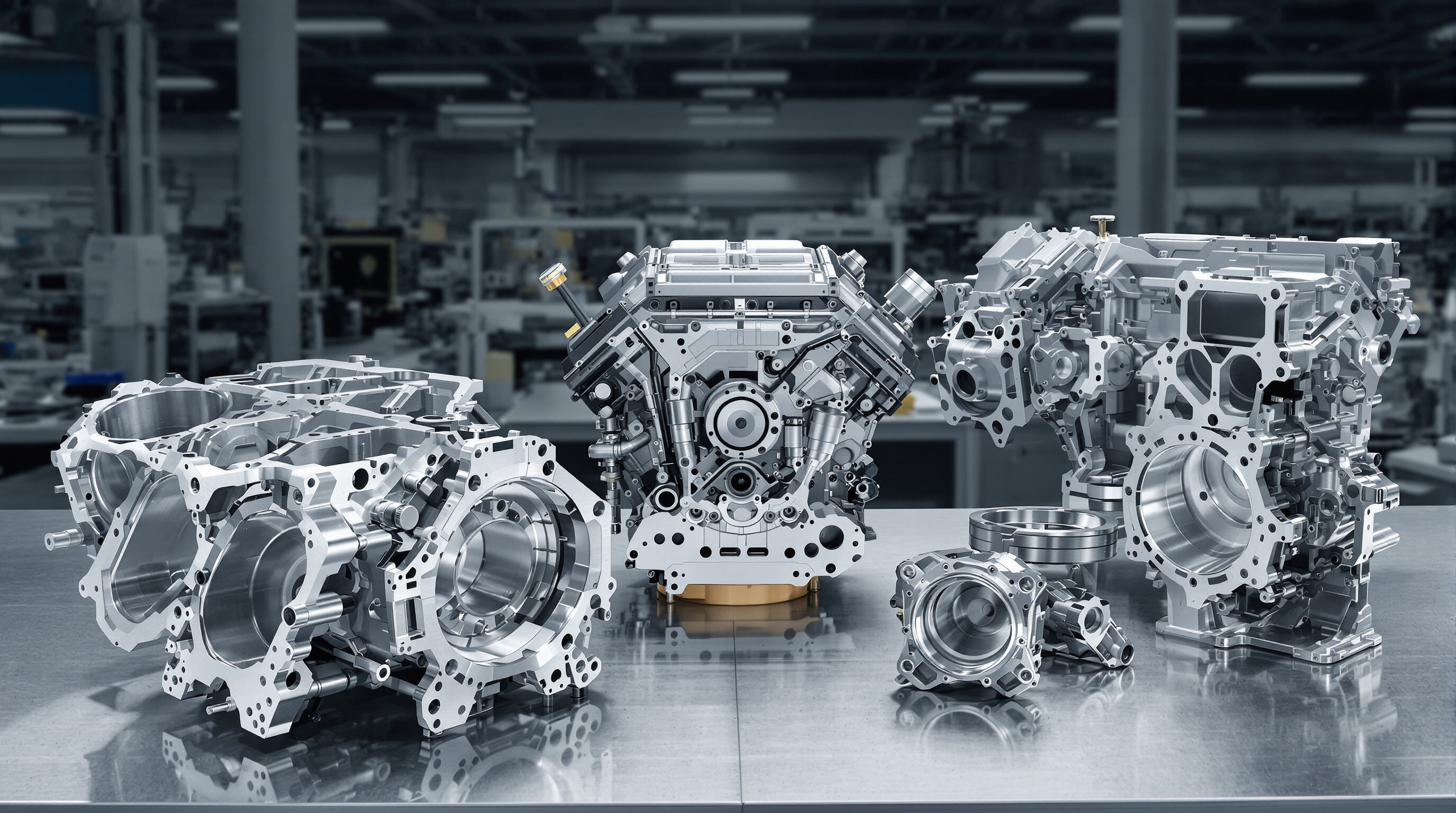

The use of CNC machining has revolutionized how car makers create engine parts with incredibly tight tolerances at the micron level. This kind of precision is what makes it possible to get better fuel burning and lower pollution levels from vehicles. When looking at things like cylinder heads and intake manifolds, these parts have all sorts of complicated shapes inside them including coolant channels and air intake openings. Modern manufacturing can cut these features within just 0.025 mm accuracy, which helps maintain good seals between components while also allowing air to flow through the engine properly. Such exactness matters a lot when building today's high performance engines.

High-performance engines operate under extreme conditions, with temperatures exceeding 300°C and intense cyclic stress. CNC-machined components like turbocharger housings and piston crowns increasingly use nickel-based superalloys and carbon-reinforced composites. These materials maintain structural integrity at high temperatures while reducing component weight by 15–20% compared to traditional cast iron.

As automakers transition to electric vehicle (EV) platforms, CNC machining supports the production of aluminum engine blocks that are 40% lighter than conventional designs. A recent EV development project achieved a 12% increase in energy efficiency by integrating precision-machined cooling channels and weight-optimized ribbing structures into aluminum block designs.

The automotive industry is shifting toward aluminum-magnesium composites and titanium alloys for critical engine components, driven by demands for fuel economy and corrosion resistance. Industry reports indicate that over two-thirds of new engine designs now incorporate these advanced alloys, reducing engine mass by an average of 22% without compromising durability.

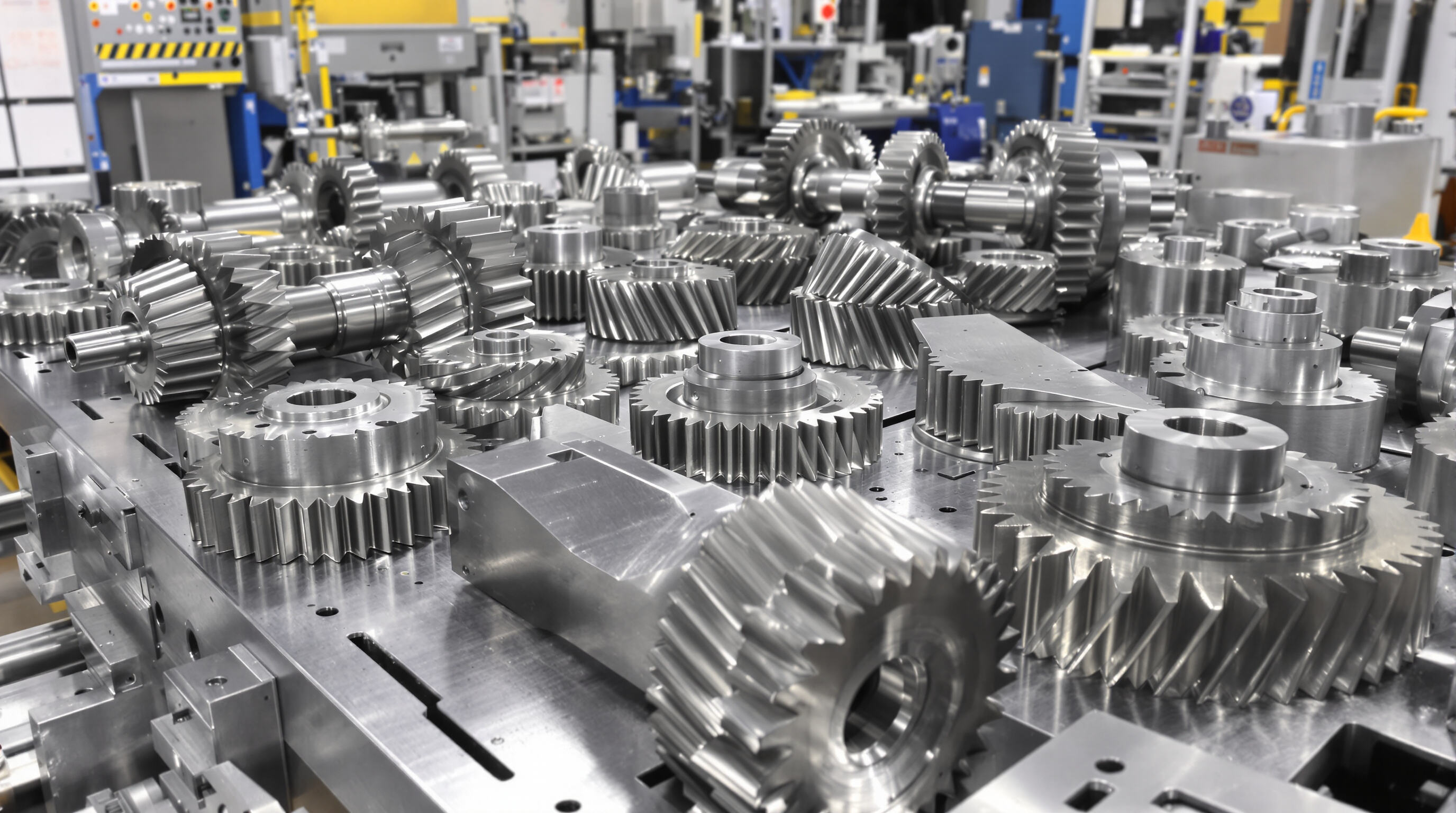

When it comes to drivetrain components, CNC machining can hit tolerances as tight as plus or minus 0.005 mm. This level of accuracy makes sure those gear teeth mesh properly and transfers power efficiently throughout the system. The multi-axis CNC machines are particularly good at handling spiral bevel gears, keeping flank angle deviations under 0.1 degrees. What does this mean for car manufacturers? Less noise coming from modern automatic transmissions is just one benefit. Looking at contact patterns between gears, CNC produced parts show about 25% better alignment than what we see with traditional manufacturing techniques. And let's not forget about longevity either these improved components can last around 40,000 additional operational hours before needing replacement in differentials alone.

The automated 5 axis CNC cells churn out about 3,800 transmission shafts each week, with nearly perfect dimensional consistency at 99.97%. Laser measurement systems check every fiftieth part that comes off the line, which has cut down scrap rates to just 0.8%. That's way better than what we typically see in manual operations where scrap can hit around 3.2%. Such consistent results mean car manufacturers can use standardized parts across their entire range of 14 different vehicle models. And they still meet those strict ISO 1328 standards for gear quality. Makes sense really when considering how much money these improvements save in production costs alone.

The CNC machining process creates suspension control arms and brake calipers down to the micron level, which means all those little parts like ball joints, sliding pins, and braking surfaces fit together just right. When components are made this precisely, it makes a real difference in how vehicles handle and respond when brakes are applied. A recent study from 2024 on automotive safety found something interesting about brake rotors too. The research showed that when these rotors have a surface roughness measurement under Ra 0.8 microns, they actually cut down on pad glazing problems by around 27% compared to what we typically see with standard cast rotors. That kind of improvement matters for both performance and longevity.

Components that are critical for safety like ABS valve bodies and electronic parking brake actuators need really tight dimensional control during manufacturing, typically within plus or minus 0.01 millimeters. The CNC machining process is what makes sure these parts don't leak hydraulic fluid and keeps sensors properly calibrated so they work correctly with modern driver assistance tech. Some recent tests have found that when aluminum alloy steering knuckles are made using CNC machines, they can handle more than a million and a half fatigue cycles under simulated pothole impacts. That kind of endurance speaks volumes about their reliability over time in real world driving conditions.

Car manufacturers are increasingly turning to CNC machining paired with cutting edge materials such as sintered carbon ceramic composites for their brake discs and chromium molybdenum steel when making suspension components. What makes these materials stand out is their ability to handle heat better than regular cast iron, roughly between 40 to maybe even 60 percent improvement in thermal stability, plus they weigh significantly less too. Looking ahead, recent market studies suggest there will be massive growth in demand for these premium braking solutions. By around 2033, we're talking somewhere close to $38 billion worth of business, driven largely by new safety standards across the automotive sector and the rapid expansion of electric vehicle production lines worldwide.

When it comes to fuel rails for direct injection engines, CNC machining can hit tolerances as tight as 0.01 mm or better, which means fuel gets distributed much more evenly throughout the engine. Some research published last year looked at how these machined fuel rails perform versus cast ones, and what they found was pretty interesting – pressure variations dropped around 18%, leading to better combustion overall. Getting all those components to work together properly is no small feat either. Fuel injectors and various sensors need to fit just right, something that really requires the kind of precision only possible with those multi-axis CNC machines we see in modern manufacturing shops today.

Stainless steel (grades 304/316) and nickel-based alloys such as Inconel 718 are standard for exhaust manifolds and turbocharger housings due to their ability to withstand temperatures above 900°C. Advances in CNC tooling now allow efficient machining of these hardened materials, cutting production time by 22% while preserving fatigue resistance in high-thermal-cycle environments.

With CNC machining, engineers can now create working prototypes that look almost identical to what will eventually go into mass production. Take electric vehicle battery housings as an example. The 5 axis CNC machines used here hit those really tight tolerances around plus or minus 0.05 mm which matters a lot when it comes to managing heat properly. Looking at some recent numbers from the industry in 2025, there's been quite a jump in efficiency too. These fast moving CNC setups cut down on how long it takes to make prototypes by about half compared to older techniques. What makes this possible? Well, spindle speeds that go well beyond 60 thousand RPM combined with smart software that optimizes cutting paths automatically through artificial intelligence algorithms. Pretty impressive stuff when you think about it.

One major auto parts manufacturer managed to slash their time from prototype to production by almost half when they started blending 3D printing with traditional CNC methods. The trick was using additive manufacturing to create those intricate inner parts while still relying on CNC machines for the outer surfaces that need to handle real stress. They hit nearly perfect measurements at 98% accuracy for aluminum motor mounts used in electric vehicles. And there's another bonus too material waste dropped by around a third, which helps them meet their green targets without having to compromise on how well the parts actually work in real world conditions.

3D printing definitely has its advantages when it comes to design freedom, but when we're talking about actual performance testing, CNC machining still holds the edge. Take transmission prototypes made from 7075-T6 aluminum for instance these can handle around 290 MPa of stress before failing, which is almost twice what the 3D printed versions manage at their 160 MPa limit. What makes CNC machining stand out even more is the precision factor. The tolerances are way tighter too about plus or minus 0.005 mm compared to the much looser 0.2 mm range seen in most printing processes. This matters a lot for parts like turbocharger housings where proper sealing is absolutely essential. Recent tests conducted in 2025 have confirmed this gap in performance between the two manufacturing methods remains significant.

When advanced 3D scanning meets CNC machining, it becomes possible to recreate those hard-to-find old parts with almost perfect accuracy these days. We're talking around 99.7% match, which is pretty impressive stuff. Take one recent car restoration job where they scanned parts using CT technology and then machined brand new nickel alloy brake calipers. These new parts actually lasted longer than the original cast iron versions, showing about 28% better wear resistance over time. Looking at industry trends, the market for aftermarket CNC services seems set for steady growth. Experts estimate around 19% annual expansion until 2030 as more people seek out custom modifications and performance enhancements for their vehicles.

CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. It's used to produce complex parts with high precision.

CNC machining provides high precision and repeatability, making it ideal for manufacturing automotive parts that require tight tolerances and durability.

Lightweight materials improve vehicle fuel efficiency, reduce emissions, and enhance performance by allowing manufacturers to optimize designs without compromising strength.

CNC-machined components offer precise fit and function, ensuring optimal airflow and fuel distribution within the engine, leading to more complete and efficient combustion.

Materials like nickel-based superalloys, aluminum-magnesium composites, and titanium alloys are now commonly used to improve heat resistance, reduce weight, and enhance strength in automotive components.

While 3D printing excels in rapid prototyping and complex geometries, CNC machining is preferred for parts that require high strength, precision, and durability.