Getting precision right in metal fabrication means components actually fit what they need to do, and this matters a lot for how things work in places like planes and cars. Take aerospace manufacturing for instance. The specs there are super tight sometimes down to 0.0005 inches. To put that into perspective, even something as small as a strand of hair at about 0.002 inches could cause serious problems if it gets into the mix. When parts don't match these requirements, whole systems might fail catastrophically. Looking at automotive applications, fuel injectors need pretty much spot on measurements too around plus or minus 0.001 mm. Without such accuracy, engines just won't perform properly, and emissions control becomes much harder to manage effectively.

Even minor fabrication errors cascade into significant consequences:

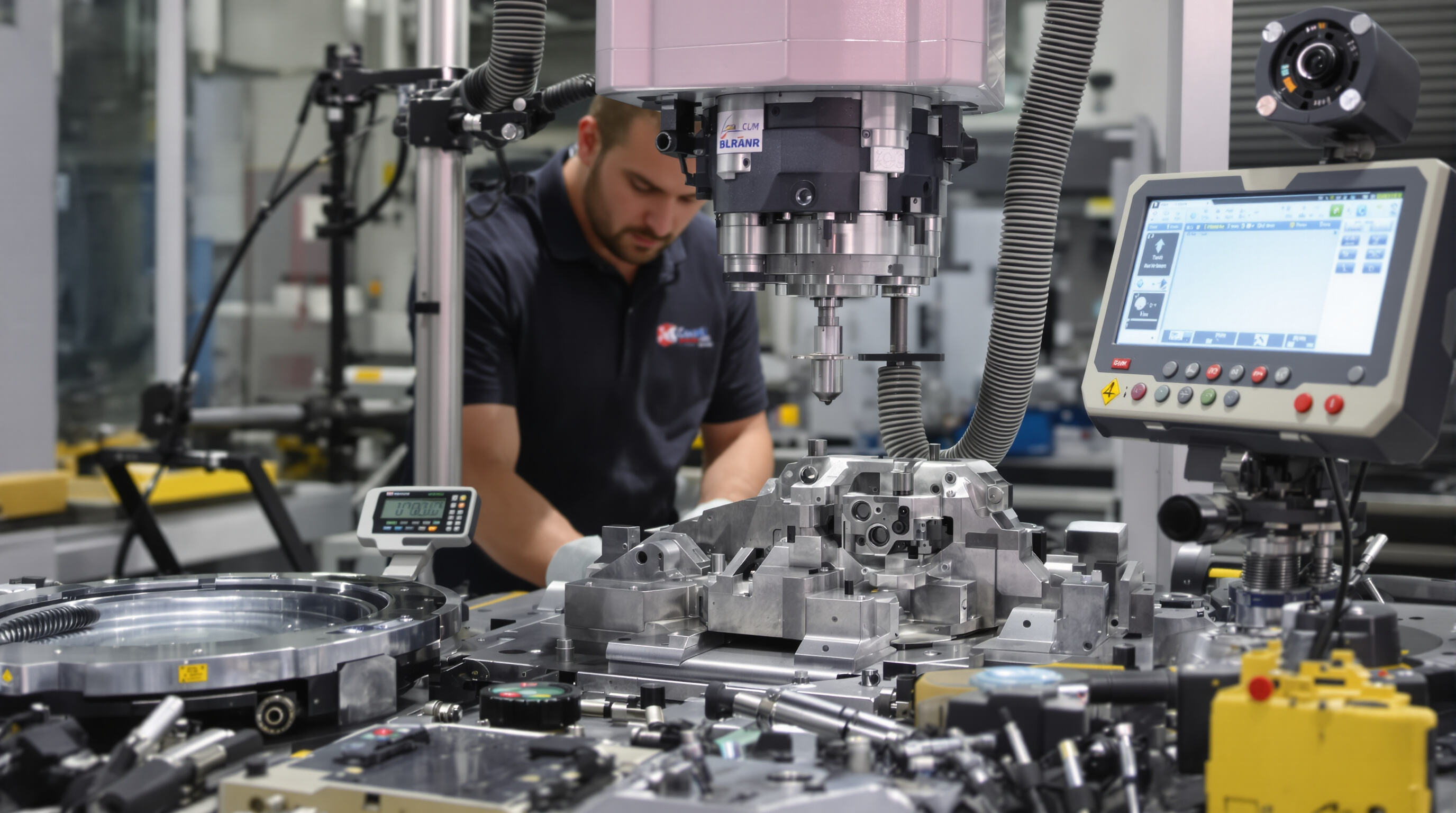

CNC technology changed the game for metal fabrication shops everywhere, allowing them to hit accuracy targets down to about 0.1%. The whole point of these computer controlled systems is they cut out those pesky human mistakes that happen during manual work. With pre-programmed paths guiding cutting tools, even complicated shapes in metals such as aluminum or stainless steel come out exactly right according to blueprints. Some advanced multi axis machines can get really precise too, sometimes hitting plus or minus just 0.005 millimeters. That kind of tight control matters a lot when making parts for airplanes or medical devices where everything needs to fit together perfectly without any gaps or misalignments.

Laser cutters and plasma systems today are really good at maintaining tight dimensions, especially when working on complex shapes in metal sheets. Take fiber lasers for instance they can cut with kerf widths down around 0.1 mm, which means less scrap metal going to waste. At the same time, these machines can still move pretty fast, cutting at speeds approaching 150 meters per minute without sacrificing quality. When manufacturers pair this equipment with smart nesting software, they typically see about a 15% improvement in how efficiently they use materials. That translates to real savings on projects, something shop owners appreciate when looking at their bottom line.

Automated welding cells equipped with vision systems ensure uniform weld seams, even for high-volume production. Robotic arms programmed with path correction algorithms achieve positional accuracy within 0.02 mm, reducing defects like porosity by 60% compared to manual methods. This consistency is vital for structural integrity in automotive frames and pressure vessels.

Top fabrication shops are starting to integrate sensors along with AI-based analytics right into their machining processes these days. According to research published last year in the field of precision engineering, when machines can correct errors as they happen, manufacturers see around a 40 percent drop in waste material because the system adjusts things like how fast the cutting tool moves or how much force it applies. What makes these feedback systems so valuable is their ability to adjust on their own for worn tools or changes caused by heat buildup throughout long shifts. This keeps parts within tight tolerances even during continuous operation all week long without human intervention.

Quality control in metal fabrication really depends on having good precision measurement tools. When it comes to checking those tight specs, manual tools such as calipers and micrometers are still going strong, especially when verifying components that need to be accurate within about 0.001 inch tolerance. Digital gauges have their place too, mainly because they can record measurements instantly which helps track what's been done where. And then there's the big guns for complicated shapes. Coordinate Measuring Machines, or CMMs as they're called, combine touch probes with optical sensors to get super close to perfect readings around 99.9 percent accurate. These machines basically compare actual parts against the 3D computer designs to make sure everything matches up.

Quality control these days relies heavily on automated inspections throughout different production phases. When manufacturers check parts while they're still being made, especially with those laser scanning systems, they spot size problems early on. This catches issues before they become big headaches, cutting down scrap materials somewhere around 18 to maybe 25 percent when compared to fixing things after everything is already built. For stuff that needs to hold weight or过Ⅲ heavy loads, companies turn to special tests that don't damage the product itself. Think ultrasonic waves that can see inside metal components or those colorful dye tests that highlight hidden cracks. These methods keep structures safe without breaking them apart first, which matters a lot when safety is on the line.

This multilayered approach ensures compliance with ASME Y14.5 standards while meeting client-specific requirements for aerospace, automotive, and medical equipment manufacturing.

Critical alignment features demand tighter tolerances than non-functional elements. A slot for fastener movement might require ±0.002" precision, while a ventilation hole could tolerate ±0.020" variations. Applying GD&T (Geometric Dimensioning and Tolerancing) principles ensures fabricators interpret positional tolerances correctly—specifying MMC (Maximum Material Condition) for press-fit components prevents assembly errors.

The fact that AISI 304 stainless steel has about 40 percent better machinability than titanium really changes how we approach CNC tooling work. When engineers get together to pick materials, they avoid those classic mistakes where someone might suggest aluminum for something that needs to handle extreme heat when actually Inconel alloys would be far more suitable. These collaborative sessions tend to lead to interesting combinations too. We see plenty of shops mixing laser cutting techniques for complex designs with traditional brake forming methods when structural bends are needed. It's not uncommon for these hybrid approaches to come out of those team meetings where everyone brings their different expertise to the table.

When putting together an RFQ document, don't forget to include those material certifications like ASTM A36 standards. Surface finish specs matter too, so something like Ra less than or equal to 32 micro inches should definitely go in there. And let's not overlook inspection details either CMM verification covering all those critical features makes sense for most projects. We've actually seen data showing that when RFQs clearly state tolerance requirements, companies end up having about half as many quality issues down the road. Speaking of things to think about early on, secondary processes are worth mentioning right from the start. Take passivation for example it takes around 2 to 3 extra days during production but helps prevent parts from failing prematurely due to corrosion problems. A little planning at this stage can save a lot of headaches later.

When looking for a good metal fabrication partner, there are really three main things worth checking out. The shop needs to have up to date equipment these days. Look for places that run CNC machines, laser cutters, and robots doing the welding work since this helps them hit those tight specs around plus or minus 0.005 inches tolerance. Certifications matter too. Most serious buyers care about ISO 9001 quality standards and AWS D1.1 welding certifications, something that over two thirds of industrial clients actually put high on their list based on recent surveys. And don't forget to dig into what kind of projects they've handled before. Manufacturers report that nearly nine out of ten want partners who know their stuff in specific application areas. Why? Because when a fabricator messes up on precision parts, it can really eat into the bottom line, adding anywhere from 18 to 22 percent extra cost to production runs according to Ponemon's latest research findings.

When working on really complex designs that need precision down to fractions of a millimeter, around 8 out of 10 engineers suggest teaming up with fabricators who specialize in complicated jobs. These kinds of shops have both the fancy equipment and the know-how to tackle problems that come up during manufacturing, stuff like when aluminum parts warp from heat or stainless steel components twist unexpectedly after processing. Looking at actual project outcomes shows something interesting too – work done with these specialized partners tends to have about 40 percent fewer size-related mistakes than projects handled by regular fabrication companies. That kind of track record makes it pretty clear why so many professionals insist on finding manufacturers with specific experience in their particular field.

Key Partner Selection Criteria (2024 Survey Results)