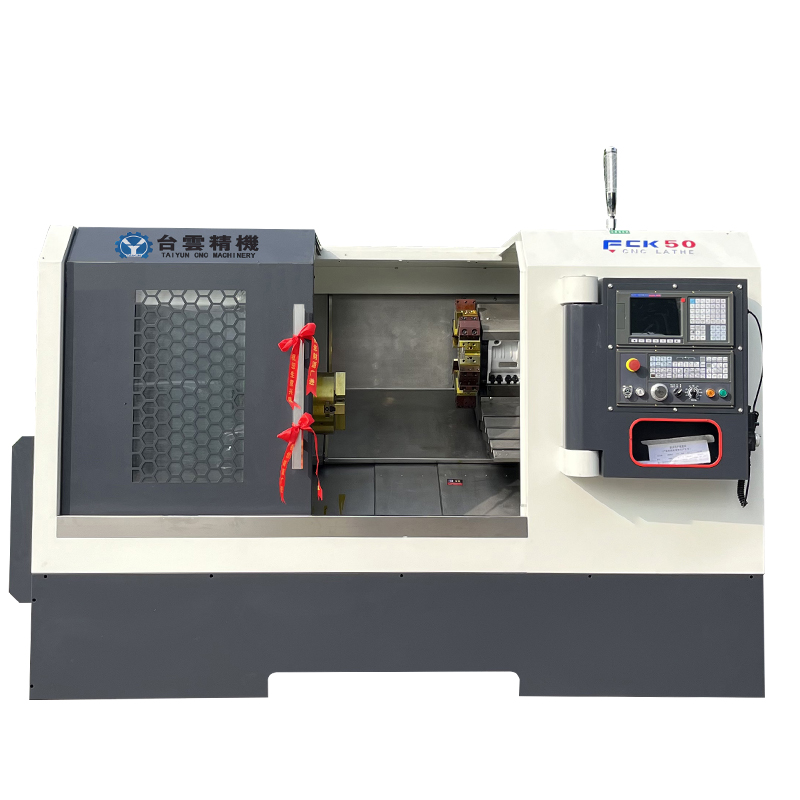

The FCK50 series multifunctional CNC lathe is a high-speed precision CNC machining equipment produced by our company with the introduction of Japanese technology. The main supporting components are all products from well-known domestic and foreign manufacturers, and the key parts are all completed by imported precision pentahedral machining centers to ensure manufacturing accuracy.

This machine tool can process shaft and disc parts, turn internal and external surfaces of threads, arcs, cones, and rotating bodies, and efficiently, massively, and accurately process rotating body parts. Reasonable matching of the stiffness of components such as the spindle, bed, and tailstock in the design greatly improves the rigidity of the entire machine and ensures stability during heavy cutting. Therefore, the machining accuracy of the outer circle of this machine tool can reach IT6~IT7 level. As a universal machine tool, it is particularly suitable for efficient, large-scale, and high-precision machining of rotating parts in industries such as automobiles, motors, bearings, and hydraulics.

FCK50 inclined bed CNC lathe

Support customization

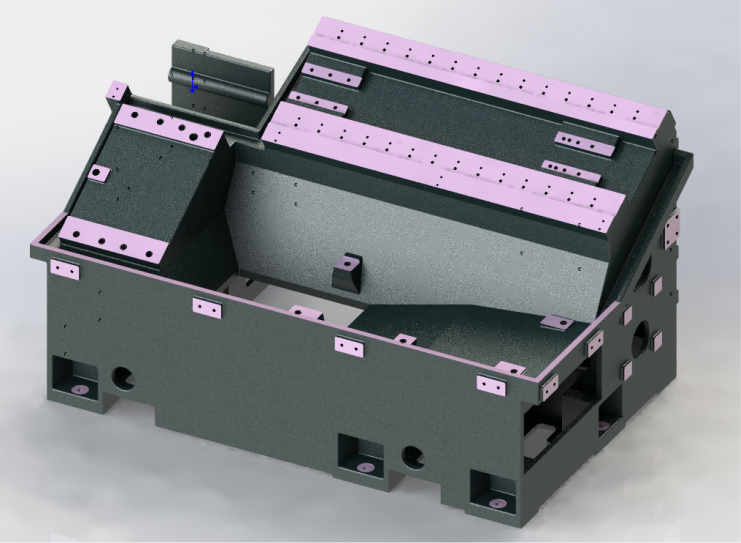

FCK50 series multifunctional CNC lathe, the bed is made of box-shaped structure and strong cast iron (HT-300), cast in one-piece molding casting technology, and it is finished by clamping and processing with a high-precision machining center. It adopts a high-rigidity 45-degree inclined back integral bed, which is convenient for chip removal. It is equipped with a separation sink to completely eliminate leakage and is easy to maintain. Therefore, it has the characteristics of strong overall rigidity, good machine tool accuracy retention and high reliability.

The FCK50 series multifunctional CNC lathe adopts a high rigidity spindle unit structure. Internal closed grease lubrication can ensure the high-speed and smooth operation of the spindle. The motor adopts AC servo motor with continuously variable speed, power of 5.5 KW, large torque output and wide range, and high torque output at low speed, which is suitable for heavy cutting. The headstock has no gear structure, which greatly reduces noise and vibration.

It adopts hollow (optional solid, chuck) hydraulic chuck and high-speed oil cylinder, and is equipped with foot switch, which makes the workpiece clamping convenient, safe and reliable.

X and Z axis feed transmission adopts Taiwan's large diameter and high precision (C3 grade), and applies preloading and preloading.

X and Z axis feed adopts Taiwan (P-class RG45) or THK ball line rail, which has strong load-bearing capacity.

Equipped with screw rail lubrication system, forced lubrication throughout the process to minimize friction, and protected by stainless steel telescopic cover.

Both the X and Z axes use servo motors, the torque of the X axis motor is 7.5 N.m, and the torque of the Z axis motor is 5N. m.

A : The conditions and period for the supplier to be responsible for quality: After the machine tool is accepted, it will enter the warranty period, which is twelve months. The equipment implements three guarantees and the warranty period is one year.

B : If the equipment fails during use, the supplier will respond within 2 hours after receiving the notice from the buyer and come up with a solution within 8 hours. If on-site processing is required, personnel will be assigned to the buyer within 48 hours to handle it.

C : If a failure occurs during the warranty period, the supplier will provide free repair services (except for damage to the machine tool caused by human factors by the buyer or the end user); the cost fee will be charged for failures caused by improper use.

D : After the machine tool arrives at the user's factory, if the installation and commissioning work cannot be carried out on time due to the buyer's reasons, the warranty period will expire 12 months after the arrival of the user, and the three guarantees service will no longer be provided.

E : Equipment accuracy standards are provided by the supplier with the contract.

| Location | |

|---|---|

Items |

FCK50 |

Processing range | |

| Maximum rotation diameter on bed (mm) | Φ 550 |

| Maximum cutting diameter bar (mm) | Φ 520 |

| Machining diameter under turret (mm) | Φ 300 |

| Maximum cutting length (mm) | 500 |

Itinerary and Feed | |

| X-axis travel (mm) | 500 |

| Z-axis travel (mm) | 260 |

| X-axis moving speed (mm/min) | 24000 |

| Z-axis moving speed (mm/min) | 24000 |

| Handwheel (mm) | 0.001/0.01/0.1 |

| X, Z feed speed (mm/min) | 0~5000 |

| X, Z manual feed speed (mm/min) | 0~1260 |

| X-axis repeat positioning accuracy (mm) | 0.005 |

| X-axis positioning accuracy (mm) | 0.006 |

| Z-axis repeat positioning accuracy (mm) | 0.006 |

| Z-axis positioning accuracy (mm) | 0.008 |

SPINDLE | |

| Spindle speed (rpm) | 35-3000 |

| Maximum spindle torque (N.m) | 48 |

| Spindle nose | A2-6 |

Spindle through hole bore diameter (mm) |

Φ67 |

Hollow hydraulic chuck through hole diameter (mm) |

Φ50 |

Chuck |

10 "(optional 12") |

Turret | |

Number of tool holders |

12 stations |

Tool Change Time (s) |

0.25 |

Cutter mounting size (mm) |

25×25 |

Boring tool seat mounting diameter (mm) |

Φ32 |

Tailstock | |

Tailstock travel (mm) |

350 |

Apex taper |

MT-5 # |

Main motor | |

| Main motor power (kw) | 7.5 (4500rpm) |

| Main motor torque (N.m) | 48 |

X, Z shaft Feed motor | |

| X-axis feed motor power (kw) | 2.3 |

| X-axis feed motor torque (N.m) | 15 |

| Z-axis feed motor power (kw) | 2.3 |

| Z-axis feed motor torque (N.m) | 15 |

Control System | |

| Coolant Capacity (L) | 200 |

| Motor Type (1HP) (kw) | 0.18 |

Dimensions | |

| Installation (length * width * height) (mm) | 2697/1795/1860 |

Weight | |

| Mechanical weight (kg) | 3600 |

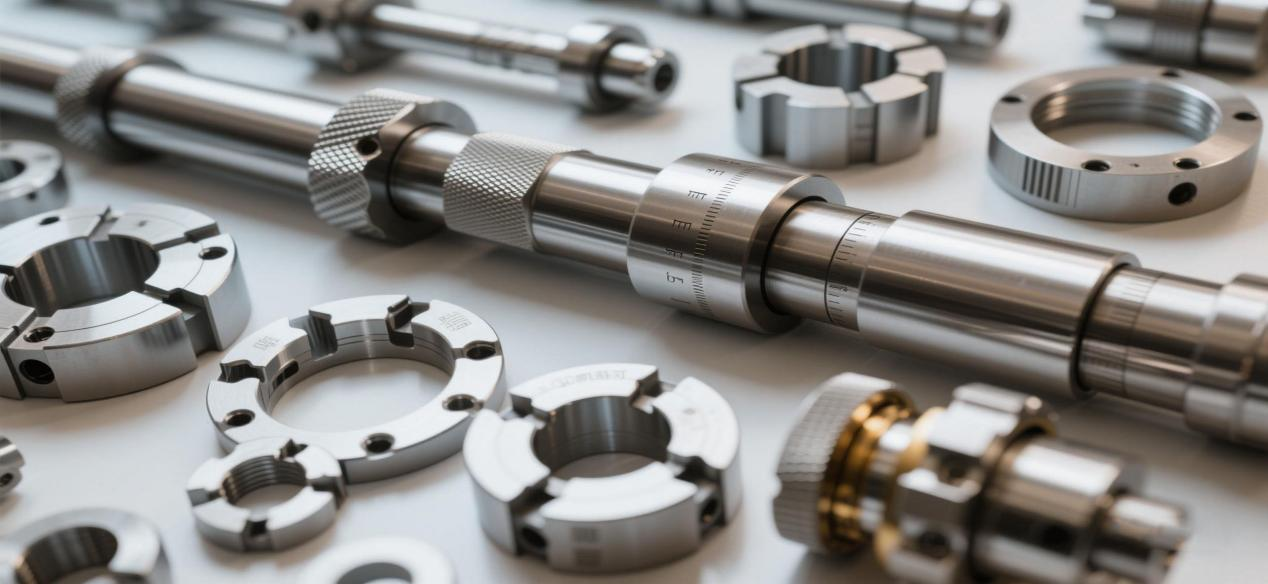

This machine tool is suitable for high-speed steel cutting tools, hard alloy cutting tools, and various high-performance cutting tools. It can process black metal, non-ferrous metal, and some non-metallic material workpieces. It can complete rough and fine machining processes such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, cutting grooves, steps, and circular arcs on the machine tool. Suitable for processing parts with large batch sizes, high machining accuracy, and high requirements for dimensional consistency.

Customer visit

Customer visit

Yes, we support ODM/OEM, and can design and customize exclusive models according to your needs.

A: Please tell me your specifications. We can choose the best model for you. You can also send us the product drawing. We will choose the most suitable machine for you.

A: 30% down payment after the contract, 70% payment before ship.ment, can be discussed according to your situation.

A: Our factory is located in Tengzhou City,Zaozhuang. China, zip code277500.Warmly welcome you to visit us.

The delivery time is 7-10 days. If you choose a special configuration, the delivery time will be correspondingly extended