TCK50 Inclined bed CNC lathe

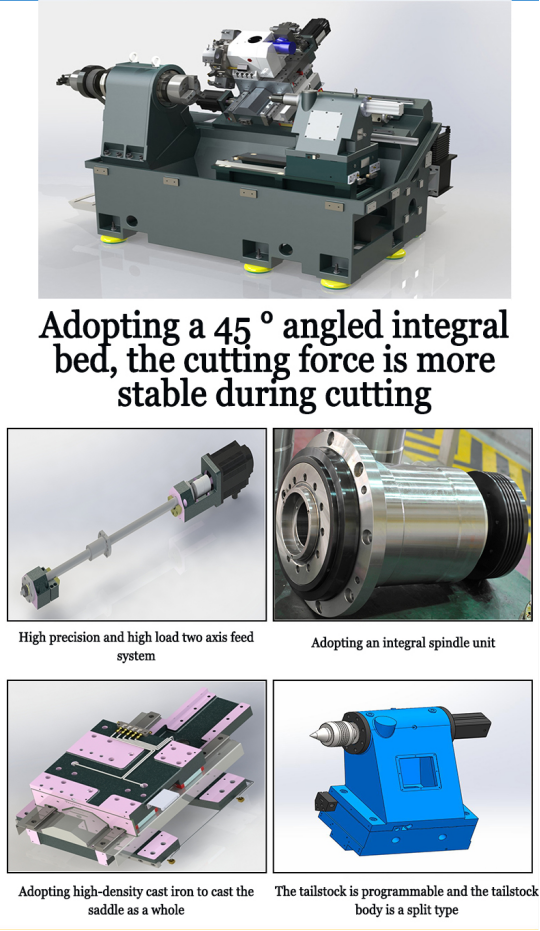

CNC Lathe Features:

The TCK50 CNC lathe is a high-precision and highly reliable inclined bed CNC lathe that can machine shaft and disc parts, turn internal and external surfaces of threads, arcs, cones, and rotating bodies, and perform batch processing on rotating body parts. The main components of this inclined bed CNC lathe, such as the bed base, bed body, and headboard, are all cast to ensure the long-term stability of the machine tool.

| Project | Unit | Specifications | Chuck diameter/type | mm | 8² | ||

| The maximum rotary diameter on the bed | mm | 500 | X-axis rapid movement speed | m/min | 30 | ||

| Maximum cutting length | mm | 480 | Z-axis rapid traverse speed | m/min | 30 | ||

| Standard cutting diameter | mm | 280 | X-axis travel | mm | 200 | ||

| Maximum cutting diameter | mm | 350 | Z-axis travel | mm | 500 | ||

| Track diameter | mm | 35 specification roller linear guide | Overall tail-off travel | mm | 400 | ||

| Screw shaft model | mm | Ф32X12 | Tailstock sleeve taper hole taper | Mohs | 5# | ||

| The maximum turning diameter on a skateboard. | mm | 350 | Standard tool post configuration | Horizontal 8-station | |||

| Spindle end type and code | A2-6 | Tool dimensions | Outer circle cutter | mm | 20×20 | ||

| Main shaft front end taper hole | 65 | The diameter of the boring bar | mm | Ф25/Ф25 | |||

| Main shaft hole diameter | mm | 50 | Can the cutting disc be selected nearby | can | |||

| Main spindle box | The range of spindle speed | r/min | 50~3000 | Maximum load capacity | Disk component | kg | 200 (including chuck and other machine tool accessories) |

| Maximum output torque of the main shaft | Nm | 200 | Shaft component | kg | 500 (including chuck and other machine tool accessories) | ||

| Spindle speed range | Continuously variable transmission | Center height | From the ground | mm | 1050 | ||

| The main motor output power | kW | 15 (15 minutes) / 11 (rated) | The gross weight of the machine tool. | kg | 3400 | ||

| Chuck | Chuck diameter/type | mm | 8² | Dimension | mm | 2500X1720X1700 | |