Five axis CNC machining has really changed how we approach precision engineering. These machines can move tools across five different directions at once, making it possible to create parts with complicated shapes that were previously impossible. Traditional machining equipment works with just three main directions X, Y and Z, but five axis machines add two extra rotations usually called A and B axes. The way these axes work together gives manufacturers something special when it comes to accuracy. Think about airplane components or car engine parts where even small errors matter a lot. Getting the hang of how all these movements interact makes a big difference in what kind of detailed work gets produced. This technology shows just how far manufacturing has come in recent years.

There's a big difference between what 3-axis, 4-axis, and 5-axis CNC systems can actually do in real world machining situations. The basic 3-axis machines work only along X, Y, and Z directions. This makes them great for simple shapes but not so good when dealing with complicated curves or undercuts. When manufacturers add that extra rotating axis to create a 4-axis system, they get better flexibility. Still, these machines struggle with really intricate designs that five-axis systems handle effortlessly. Five-axis machines bring two additional rotational axes into play. This means fewer setup changes during production runs which saves time and reduces mistakes. For shops working on high precision components or aerospace parts where tolerances matter most, going with five-axis technology is often worth the investment despite higher costs.

Five axis CNC machining brings rotational axes A and B into play, opening up new possibilities for making undercuts and working at tricky angles. What makes this setup so valuable is that it handles complex manufacturing needs where detail work matters most something standard three or four axis systems just cant manage. When shops take advantage of all that movement range, they can crank out parts with really complicated shapes like turbine blades need or the kinds of components found in medical equipment. The real benefit here goes beyond just saving time on the shop floor these machines deliver much better accuracy too. That combination of speed and precision explains why more shops keep investing in five axis technology despite the higher initial costs.

When working in industries that require really tight tolerances, 5 axis CNC machining stands out as something pretty important. These machines can hit precision down to about 0.001 inches, which makes them essential for things like airplane parts and medical equipment. Why does this matter so much? Well, these machines work differently because they can move parts around in several directions at once, which cuts down on those pesky alignment issues that plague other methods. A few aerospace companies actually did some testing with these systems and found their rejection rates dropped quite a bit for high precision parts. So basically, 5 axis machining isn't just another tool in the shop it's changing what we consider possible when it comes to making things with extreme accuracy.

Five axis CNC machining cuts down on setup time dramatically, which means machine shops can tackle complicated parts much easier while boosting productivity across the board. When there are fewer setup changes needed during production runs, factories actually save money on both time spent and worker hours too, which makes everything run smoother from start to finish. Industry numbers show something pretty impressive here too some shops report cutting their setup times almost three quarters when they switch to five axis systems. The real world impact? More products get made each day without sacrificing part quality. For manufacturers trying to keep up in today's fast paced market, this kind of efficiency is becoming essential if they want to stay ahead of competitors.

One big plus of 5 axis CNC machining lies in achieving really good surface finishes on parts. When the cutting tool stays engaged with the material throughout most of the process, it cuts down on those annoying vibrations that mess up surface quality so often. The result? Manufacturers don't have to spend as much time and money on grinding or polishing after machining. Studies show something interesting too the cutting tools themselves actually last longer when used in these 5 axis setups because they wear out more evenly across their surfaces. For shops looking to cut costs without sacrificing quality, this dual benefit of better finish and longer tool life makes all the difference. That's why so many precision engineers are turning to 5 axis technology these days for complex manufacturing tasks.

The 5 axis CNC machines really cut down on costs by doing everything in one go. They slash material waste since parts don't need to be moved between different machines or set up multiple times. Production shops actually see their bottom line improve when they switch to this method. Real world data from manufacturers shows companies saving big money on both running costs and overhead expenses after adopting 5 axis tech. What used to take several separate operations on different machines can now be handled all at once, which saves time and money alike. These kinds of savings explain why so many shops in tough manufacturing markets have made the switch to 5 axis machining as part of their standard operations.

The aerospace sector relies heavily on 5-axis machining when it comes to producing those intricate turbine blades needed for jet engines. These blades must have exact aerodynamic profiles to function properly at high speeds and temperatures. The real magic happens because this tech handles complicated shapes that meet strict FAA requirements. When parts can be positioned from different angles while being machined, there's much less chance of alignment issues creeping in, which means better accuracy overall. Industry reports show that components made with 5-axis machines fail far less often in stress tests compared to traditional methods. This makes sense given how critical even minor imperfections become in aircraft components where safety margins are razor thin.

Using 5-axis CNC technology in car manufacturing has completely changed how engine parts and lightweight components get made. The machines can produce really complicated engine pieces that are both lighter and better performing than traditional methods allow. According to recent studies from automotive research firms, these advanced techniques help cars save around 15 to 20 percent on fuel when using lighter parts. What makes this possible? The machines work on complex shapes with incredible precision. Setup time drops significantly because everything gets done in one go rather than multiple steps. Plus there's less wasted material since the cutting process is so accurate, which cuts down on overall production expenses for manufacturers looking to stay competitive in today's market.

Medical professionals have found that 5 axis machining makes a real difference in their work, particularly when it comes to making those super precise surgical tools and one of a kind prosthetics. The tech basically guarantees that all those tiny scalpels and forceps meet the tough standards set by hospitals and clinics while still being incredibly accurate and reliable. And let's talk about prosthetics for a moment. With this advanced machining method, doctors can create replacement limbs that actually fit each person perfectly instead of having to settle for something off the shelf. Some recent research shows that surgeons using these specially made instruments often finish operations faster and patients tend to recover better too. Looking at how much this technology has changed things in operating rooms across the country, it's clear that 5 axis machining isn't just some fancy buzzword but an actual game changer for modern medicine.

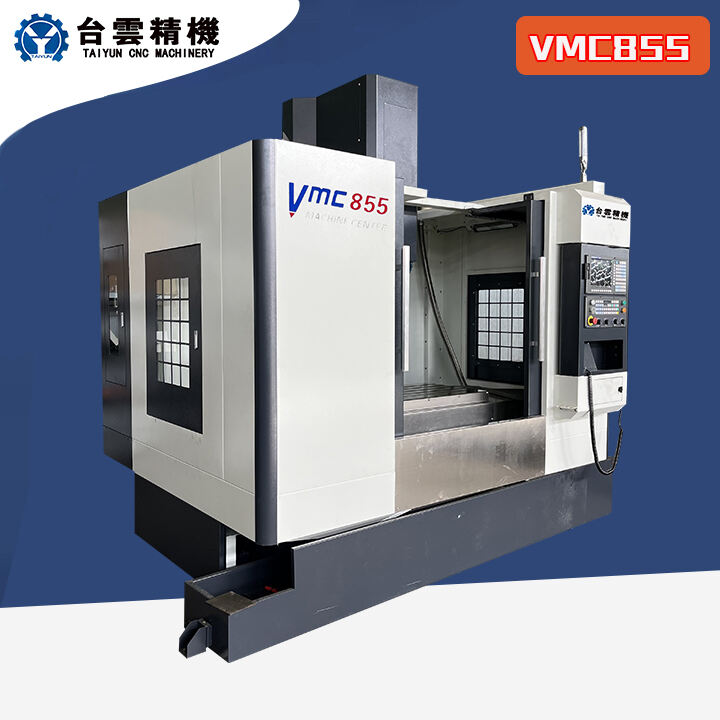

Taiyun's VMC855 CNC Machining Center was built for tough jobs, featuring solid construction that handles big workpieces without breaking a sweat. What really sets this machine apart are its upgraded tool changers, which cut down on downtime between operations and keep production moving smoothly through the shop floor. Real users report seeing noticeable gains in both output speed and component quality, something that translates directly into lower overhead expenses over time. For shops where getting precise results consistently matters most, the VMC855 remains a top pick thanks to its rugged design combined with modern tech that delivers reliable performance day after day.

The VMC650 CNC Machining Center packs impressive precision into a surprisingly small package, which makes it great for working on parts ranging from tiny gears to moderately sized components. What sets this machine apart is how fast it can cut materials without losing track of those fine details, giving manufacturers flexibility when switching between different jobs throughout the day. Factory workers who've had hands-on experience with the VMC650 often mention seeing their production numbers go up while still getting that smooth finish that customers expect. And despite its relatively small size compared to bigger machines, the VMC650 holds its own in terms of performance. Many shops find it particularly useful in tight spaces where floor room is at a premium but they still need to maintain strict tolerances on their workpieces.

Bringing AI into CNC machining is becoming a big deal these days and looks set to change how things get made on shop floors everywhere. When machines adapt themselves during operation, they actually react to differences in materials as they happen. The AI adjusts where tools cut through parts, which cuts down on how long each piece takes to make without sacrificing quality standards. What we're seeing here is real improvement both in how fast stuff gets done and how good it ends up looking when finished. Most experts think production speeds could jump around 20 percent once AI becomes standard practice across CNC shops within ten years or so. Beyond just moving faster though, there's something else happening too consistent results from batch to batch mean fewer rejects and happier customers overall. For manufacturers looking ahead, integrating smart systems seems like an obvious step forward for staying competitive in today's market.

When additive and subtractive manufacturing work together, they create something really special for making complicated designs and putting different functions into one piece. These hybrid systems mix the two approaches so companies can prototype faster, cutting down on how long it takes to get products ready for market. Looking at what's happening environmentally, studies show these systems cut down on wasted materials by around half, which means better sustainability overall. Manufacturers love being able to make detailed parts without throwing away so much stuff, plus they get all the benefits from both types of manufacturing. As CNC technology keeps changing, these hybrid setups are becoming increasingly important for shops wanting to stay competitive while also being responsible to the planet.