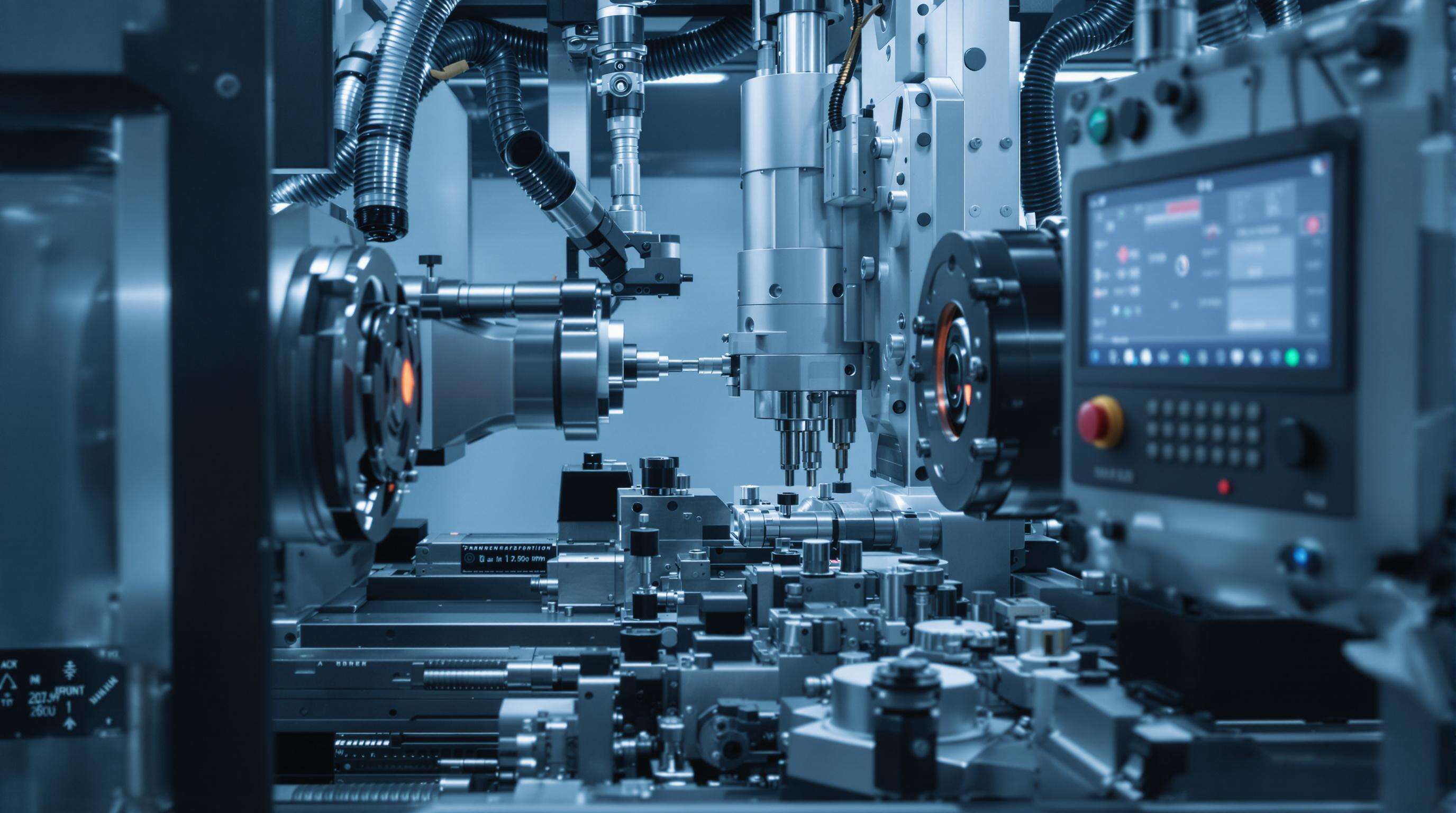

Precision machining basically means cutting away material to create parts with really tight tolerances, often below 0.025mm. When working with CNC lathes, those fancy CAD/CAM drawings get converted into machine instructions that tell the equipment exactly how much to rotate and move along different axes. The machines handle all sorts of important tasks automatically these days including things like facing surfaces, making grooves, and creating threads, all while keeping dimensions within just ±0.005mm even when dealing with tough metals like stainless steel or titanium alloys. Such fine control matters a lot in fields where mistakes cost big money, think aerospace engineering or medical device production. A tiny error measuring over 5 microns could actually cause entire components to fail completely, which nobody wants to see happen on the assembly line.

CNC lathes today can hit really tiny tolerances thanks to components like servo motors, hardened ball screws, and those linear guides we all know about. These machines typically repeat positions down to around 1 micron accuracy. The real magic happens when they detect tool deflection on the fly and adjust accordingly. Most modern setups have multiple axes working together, allowing tools to move pretty fast actually - some can spin at over 10,000 revolutions per minute without missing a beat. When manufacturers run automated calibration routines regularly, they basically cut out those pesky human measurement mistakes. A recent industry report from last year showed that shops switching to this automation saw their scrap pile shrink by almost three quarters compared to old-fashioned manual methods.

Nine-axis CNC lathes combine turning, milling and drilling all in one machine setup which cuts down on errors caused when moving workpieces around between operations. For really complicated parts such as turbine blades where concentricity needs to stay within plus or minus 0.002 mm, this integration makes all the difference. The machines come equipped with thermal compensation systems that tweak the tool path around 500 times every second against heat-induced expansion problems. This helps maintain smooth surface finishes even during those long production cycles that can last for 20 hours straight. Manufacturers report that these improvements have pushed first pass yields up to nearly 99.98 percent in mass production settings where precision matters most.

The latest CNC control systems come equipped with impressive specs like 19-bit processing power and feedback loops down to 0.1 microns, which really boosts how well they perform. What makes them stand out is their ability to compensate for when materials spring back after cutting, adjust feed rates automatically within just 0.005mm tolerance, plus run smart algorithms that can predict when tools might start deflecting during operation. A recent study from the 2024 Precision CNC Systems Report showed something pretty remarkable too. Factories that switched to these new controls saw their dimensional errors drop by around two thirds compared to older equipment. That kind of improvement means better quality parts and fewer rejects on production lines.

Modern CNC lathes now come equipped with AI vision systems and force sensors that can spot tiny deviations down to just 2 microns while running. These smart systems constantly monitor everything happening inside the machine. When they notice something off, they adjust tool positions within fractions of an inch, account for heat-related expansions, and even tweak cutting speeds on the fly. The results speak for themselves really. Most shops report around 99.7% success rate on their first attempt without needing to fix anything later. And when it comes specifically to working with tough materials like titanium, about 8 out of 10 times there's simply no need for anyone to manually go back and redo what the machine already did perfectly.

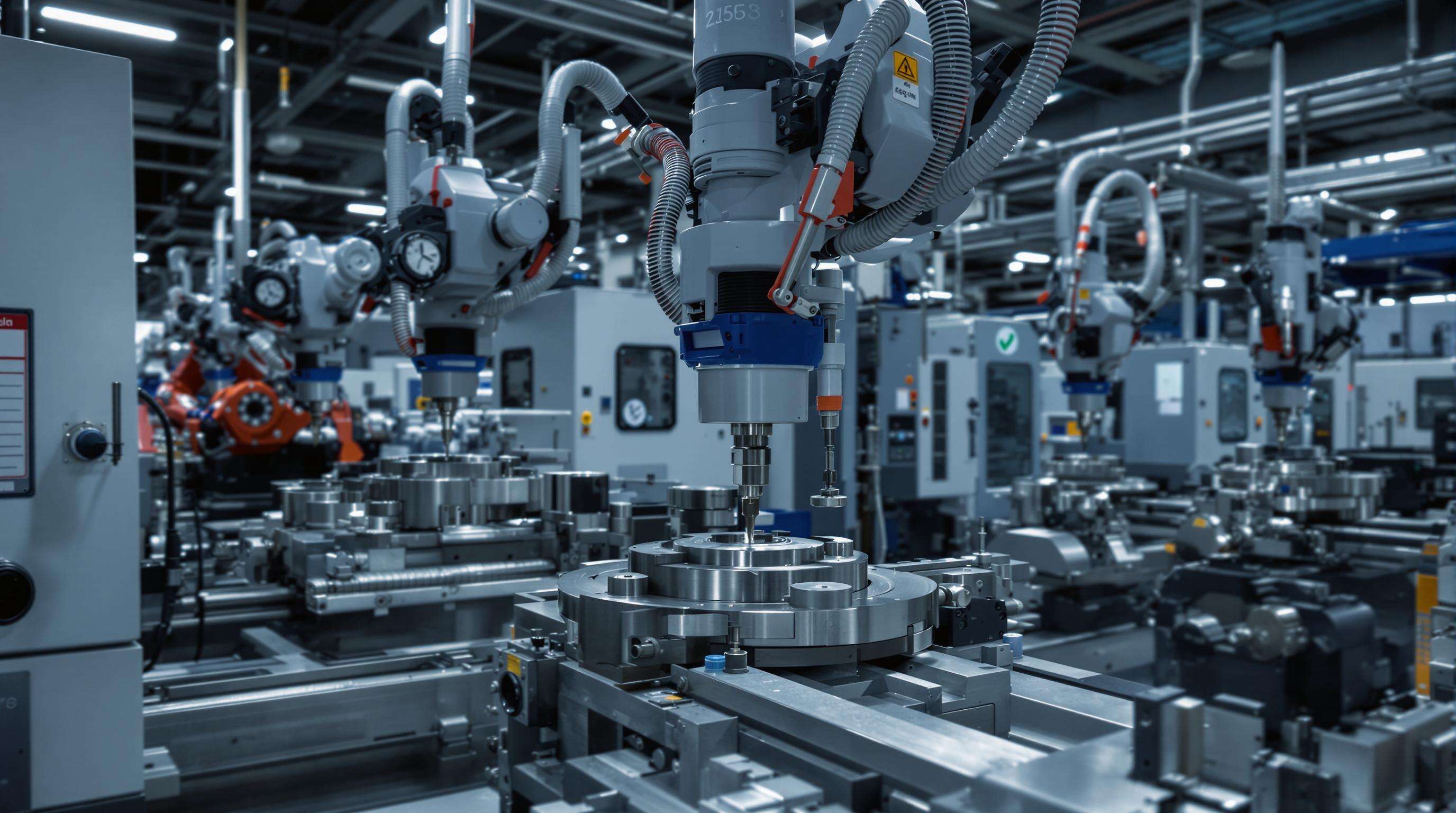

Five-axis CNC lathes with 0.5-arcsecond rotational accuracy are now standard in aerospace and other high-precision sectors. Key technologies enhancing their performance include:

| Technology | Precision Improvement | Application Example |

|---|---|---|

| Linear motor drives | ±0.8μ positioning | Optical component machining |

| Active cooling spindles | 0.0002" thermal stability | Medical implant turning |

| Hybrid ceramic bearings | 92% vibration reduction | Micro-drilling operations |

These systems maintain compliance with ISO 2768-f tolerances even under continuous 24/7 operation.

Modern CNC lathes enhance metalworking accuracy by systematically eliminating human error through automation. By executing complex operations via pre-programmed instructions, these systems deliver consistent, repeatable results unattainable with manual intervention.

CNC automation targets the three main sources of human error:

This shift reduces quality variations tied to operator dependency by 79% compared to semi-automated processes, as reported in the 2024 Precision Manufacturing Report.

Performance differences between manual and CNC lathes are substantial:

| Metric | Manual Lathes | CNC Lathes |

|---|---|---|

| Typical defect rate | 8-12% | 0.5-1.2% |

| Dimensional repeatability | ±0.1mm | ±0.005mm |

| Setup error frequency | 1/15 jobs | 1/500 jobs |

Transitioning to automated CNC systems reduces the average annual cost of machining errors—estimated at $740,000 (Ponemon 2023)—by 63%. This leap in precision is essential for meeting the stringent tolerance requirements of aerospace and medical component manufacturing.

Today's CNC lathes are equipped with solid carbide inserts and alumina ceramic materials that last around 35% longer under cutting stress compared to old school high speed steel according to Friction Dynamics research from 2023. The industry has also seen significant advances in coating technology. Titanium nitride (TiN) coatings and those resembling diamond like carbon (DLC) can cut down on friction by nearly half during machining processes. This means machines can maintain tighter tolerances even when running at higher speeds. What does this all mean for manufacturers? Less tool bending during operation and tools that simply last longer. Better surface finishes result from these improvements, something that matters a lot in sectors where precision is everything, think aerospace components or intricate medical device parts where even minor imperfections could be problematic.

What materials we choose has a big impact on how precise our parts can be. Take Aluminum 6061 for example it cuts really well but tends to warp about 0.02mm after machining unless we stabilize it thermally first. With titanium alloys things get trickier because they need very sturdy tooling just to handle the spring back effect, otherwise dimensions might drift around +/- 0.015mm. Some testing recently showed something interesting about Inconel 718 it keeps almost all (like 99.7%) of its dimensional accuracy even when stressed, especially if we use those special negative rake carbide tools during machining. This shows why getting the right tooling for each specific material matters so much for making reliable parts that actually work as intended.

More than two thirds of precision CNC operations have switched to carbide inserts when working with hardened steel these days, getting surface finishes down under Ra 0.4 microns. Ceramic tools really shine where things get hot, holding their shape even when temps hit around 1200 degrees Celsius without needing coolant. This matters a lot for making automotive camshafts since it cuts down on warping from heat. Shops are starting to see value in those hybrid tools that mix carbide bases with ceramic coatings too. These combinations tend to last about 40 percent longer when running through titanium parts continuously, which makes sense given how tough that material can be on standard cutting tools.

The aerospace, medical device, and optical industries are pushing for parts with tolerances below ±0.001mm these days. To put this into perspective, that's about 1/75th the width of a single strand of human hair, which measures roughly 0.075mm across. Modern CNC lathes handle these extreme requirements thanks to their closed-loop feedback mechanisms and direct drive spindle technology that gets rid of any play or slack in the system. Take the tiny gears found in surgical instruments for example. These miniature components need positioning accuracy better than 1 micron to function properly during delicate procedures. Manufacturers achieve this level of precision using sophisticated servo control systems paired with encoders capable of reading measurements down to sub-micron levels. The combination allows for the kind of exactness required when crafting components where even the slightest deviation could mean failure in critical applications.

When machines spin over 15,000 RPM, problems start showing up in the form of tool deflection which can reach around 5 microns when subjected to about 150 Newtons of cutting force. Thermal expansion adds another challenge too, growing roughly 0.02 millimeters for every meter of length exposed to each degree Celsius temperature change. Recent research from last year pointed out something interesting - nearly two-thirds of all those tiny machining mistakes actually come down to vibrations that aren't properly controlled during fast cutting processes. Traditional lathes just don't cut it anymore at these extreme speeds because they simply cannot react quickly enough to what's happening on the shop floor. That's where modern CNC equipment shines though, incorporating special damping features that actively counteract these unwanted movements and keep precision intact throughout production runs.

Top-tier CNC lathes employ a three-stage error compensation strategy:

These integrated technologies enable the continuous production of 0.2mm-diameter titanium pins with ±0.8µm diameter consistency, requiring precise coordination between 12-axis synchronization and 0.1µ-resolution linear scales.